Emerging from the innovative legacy of Autoline Automation, Autoa is a forward-thinking brand with a laser focus on “Robotic Welding Simplified.” With over 30 years of industry experience, Autoline has consistently pushed the boundaries of technology, carving a reputation for groundbreaking solutions in automation and robotics.

Founded in New Zealand, Autoa is dedicated to meeting the distinctive manufacturing requirements of the Australasian market. Our state-of-the-art Autoa Cells are designed and built in New Zealand, ensuring the highest quality and performance.

In a strategic move to offer customers maximum flexibility and compatibility, Autoa collaborates with renowned robotics manufacturers OTC Daihen and Yaskawa. Our modular approach allows clients to integrate any brand of welding power source seamlessly, making Autoa Cells a versatile solution for a wide range of applications.

Underpinned by Autoline’s rich history of innovation, Autoa is committed to revolutionising the engineering productivity landscape through advanced robotics and relentless dedication to customer satisfaction.

Autoa Robotic Welding Cells

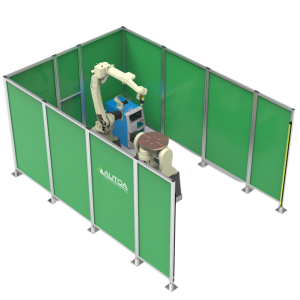

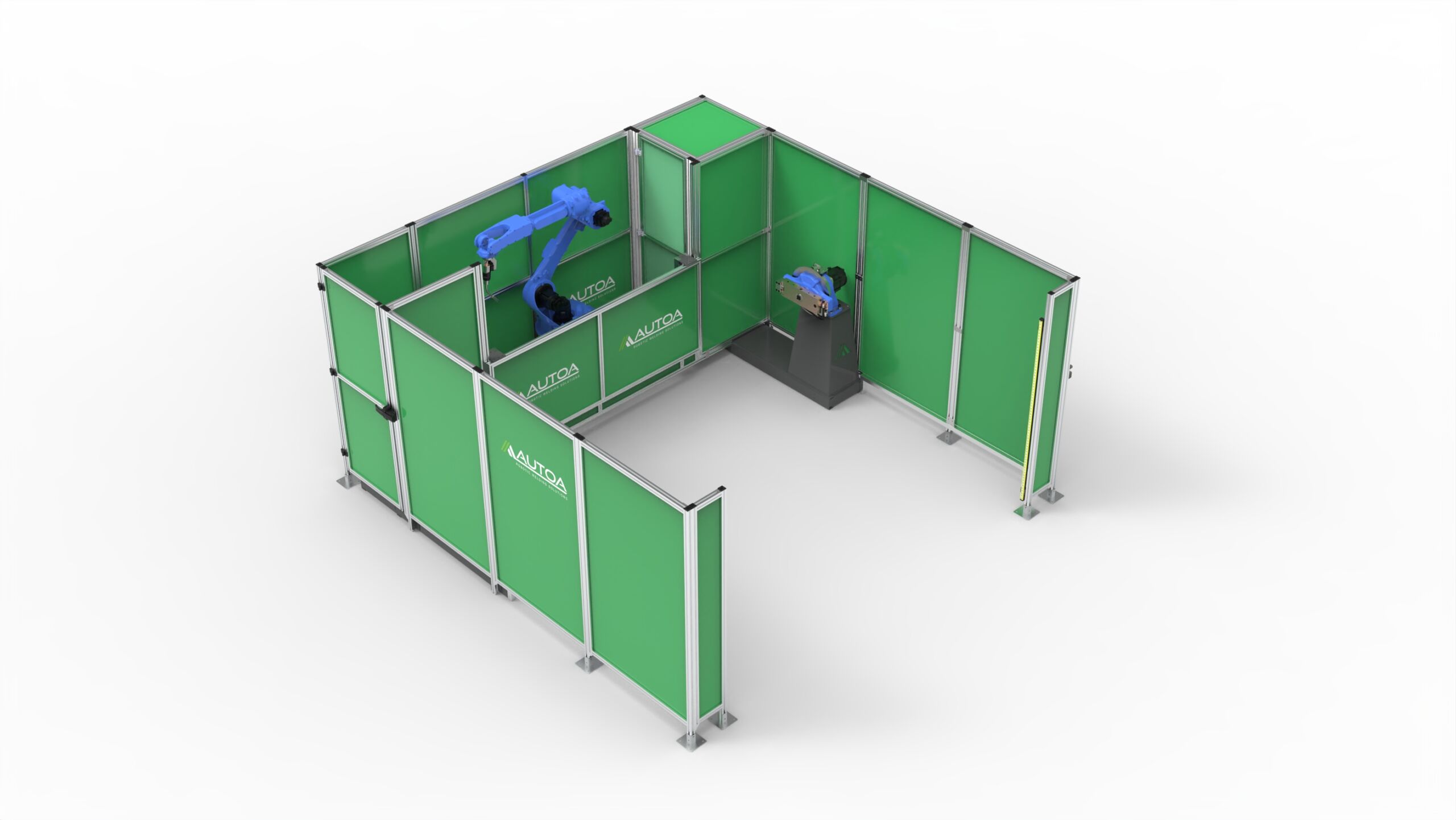

T-500 Cell

If you’re looking for a robotic welding solution to address labour shortages and quality concerns, the Autoa T-500 Cell is the perfect first step into robotic welding. Designed as a cost-effective option for businesses, this workcell features all of the pre-engineered safety and efficiency of our welding systems.

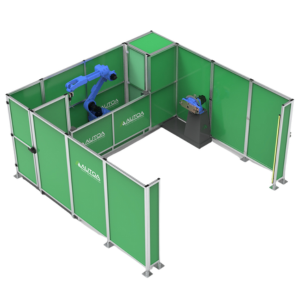

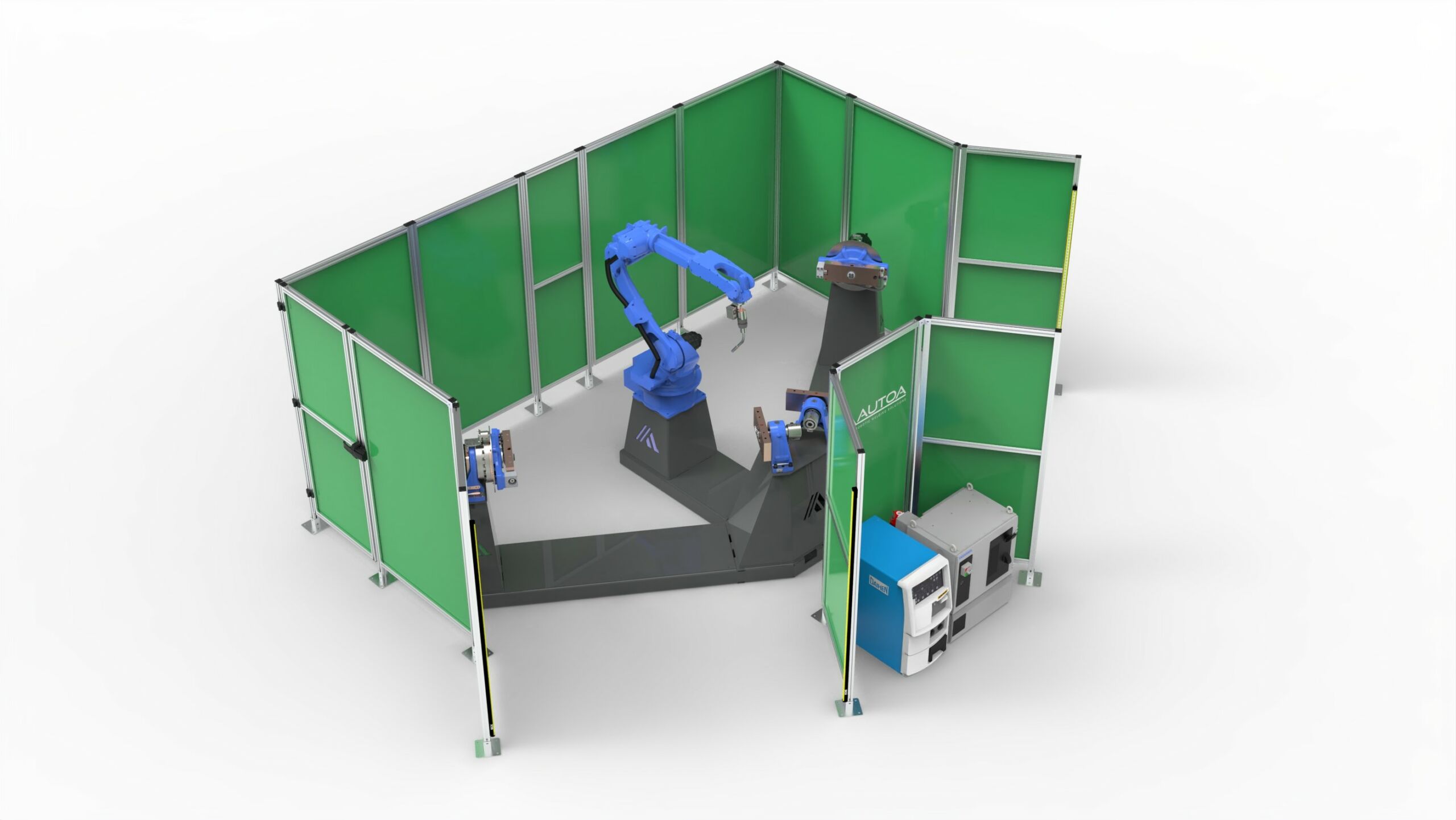

M-1200 Cell

Introducing the M-1200 robot welding cell, a compact and versatile solution for enhanced productivity and consistent high-quality welds. With its innovative rotary station, this workcell offers dual-sided productivity in a compact, manually rotated workstation. The streamlined design ensures total safety while housing the robot and weld equipment.

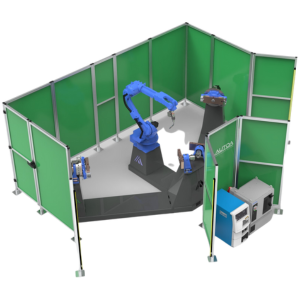

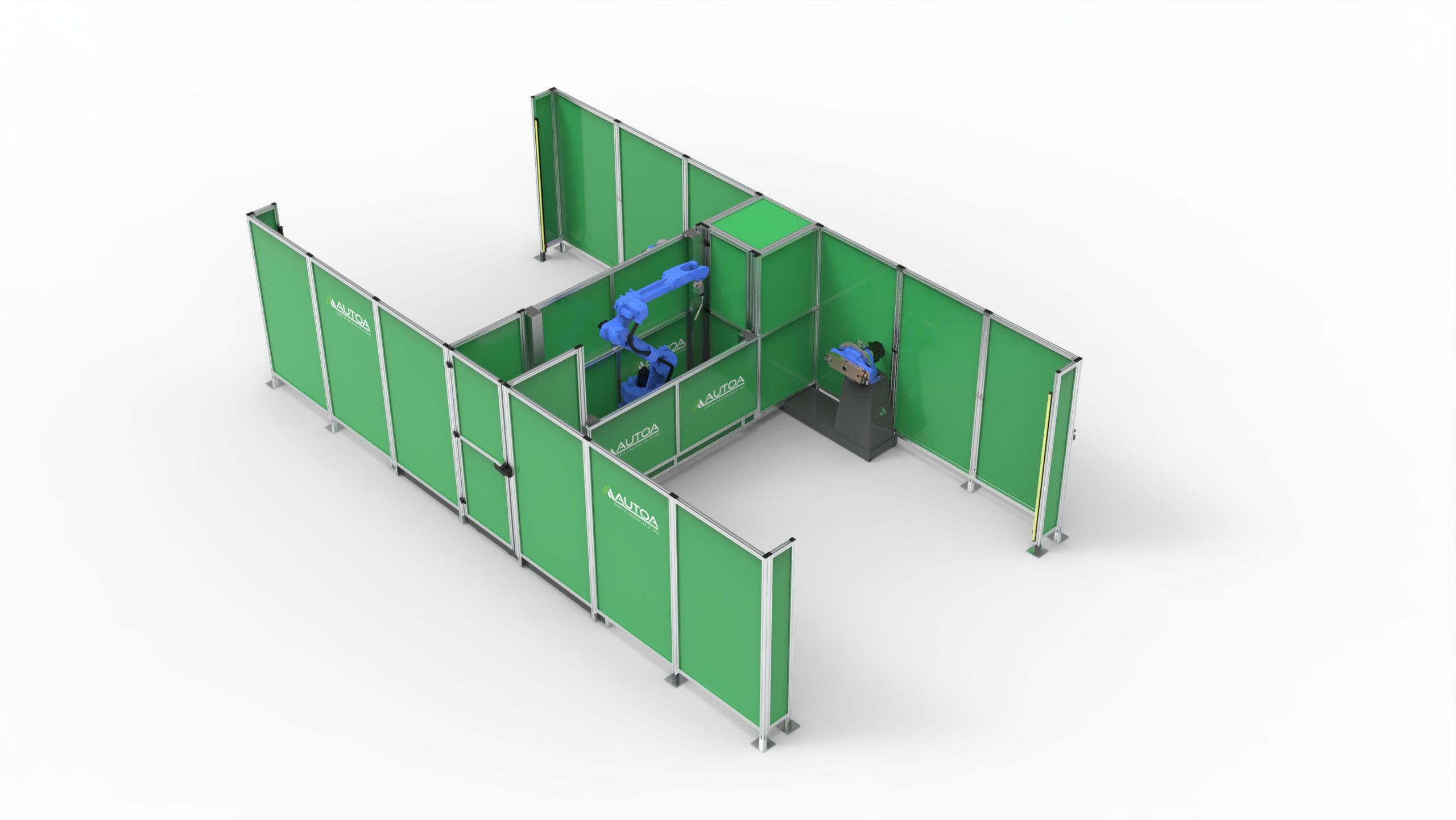

Y-1600 Cell

The Autoa Y-1600 robot welding cell is a dual-workstation system that features positioners (head and tailstock), allowing manufacturers to process different parts in each workstation or double up production on the same part. With its two-station setup, the Y-1600 enables quick changeovers for a higher mix of part variations, making it a cost-effective solution for manufacturers who need to weld multiple parts.

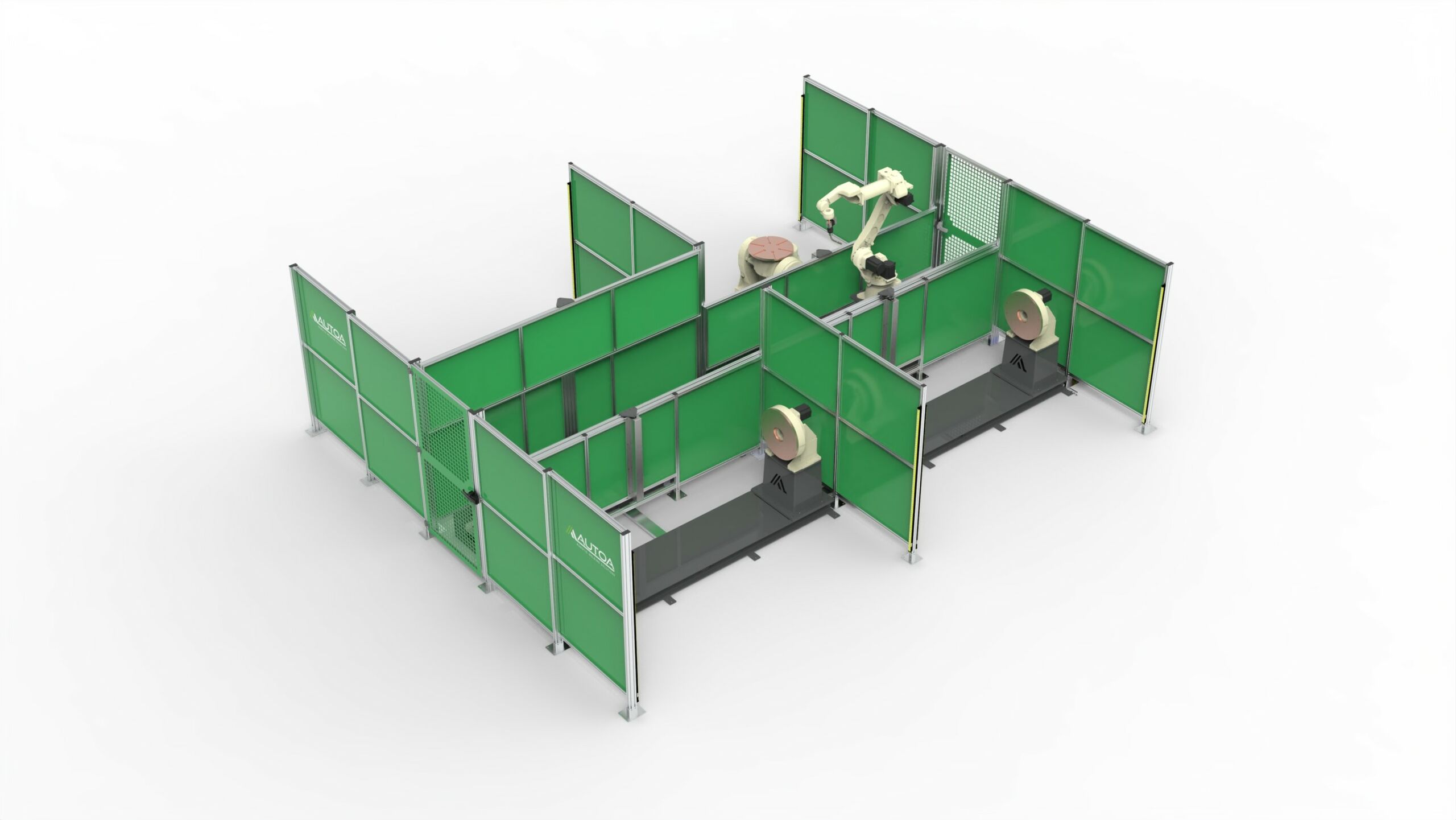

H-2800 Cell

The Autoa H-2800 robot welding cell is the ideal heavy-duty solution for manufacturers who require high-volume welding of large, heavy parts. This workcell features dual servo-controlled positioners (head and tailstock) and H-frame design enables operators to prepare work on station one while the robot welds on station two, maximizing productivity.

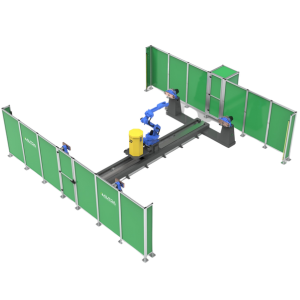

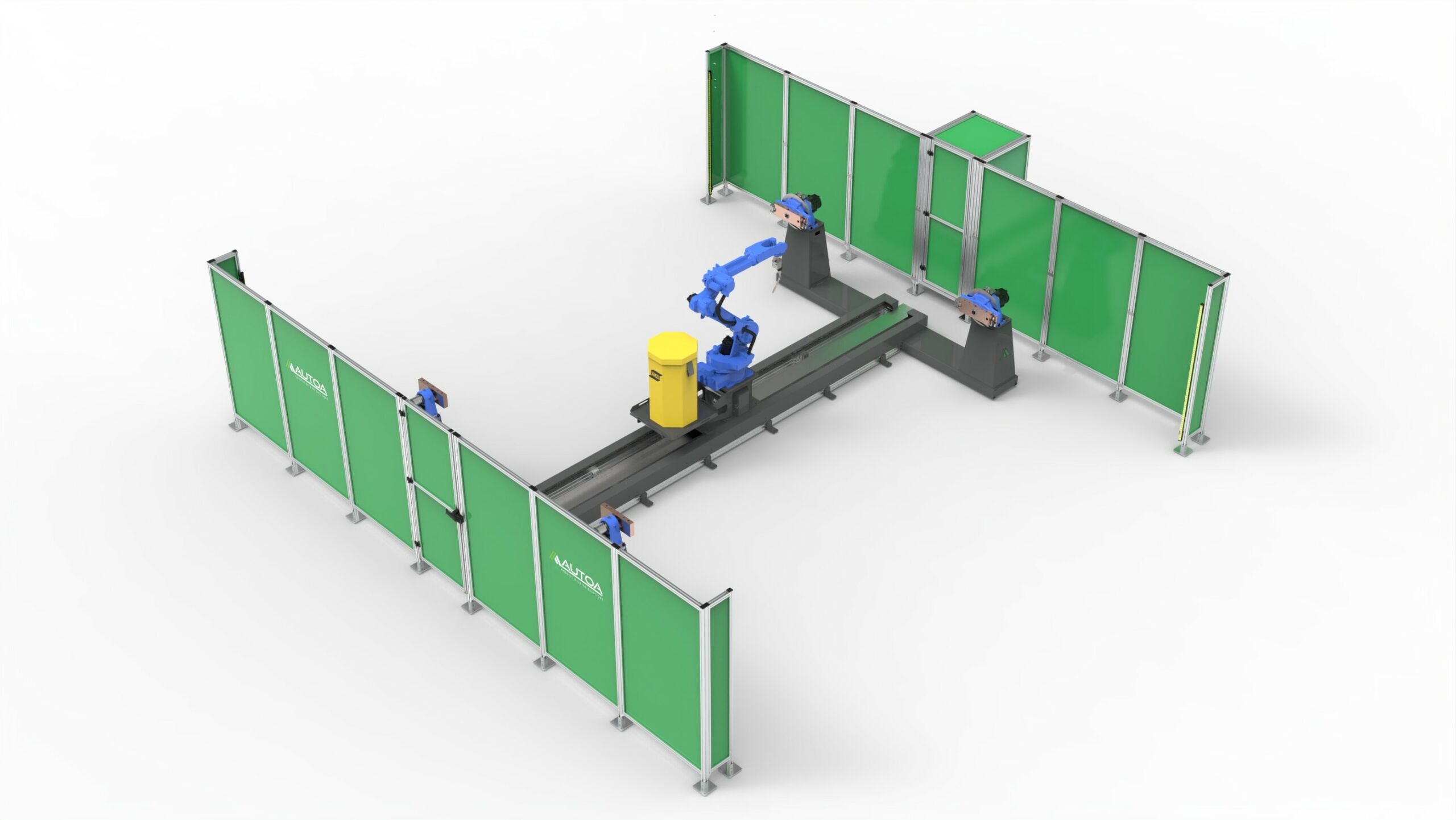

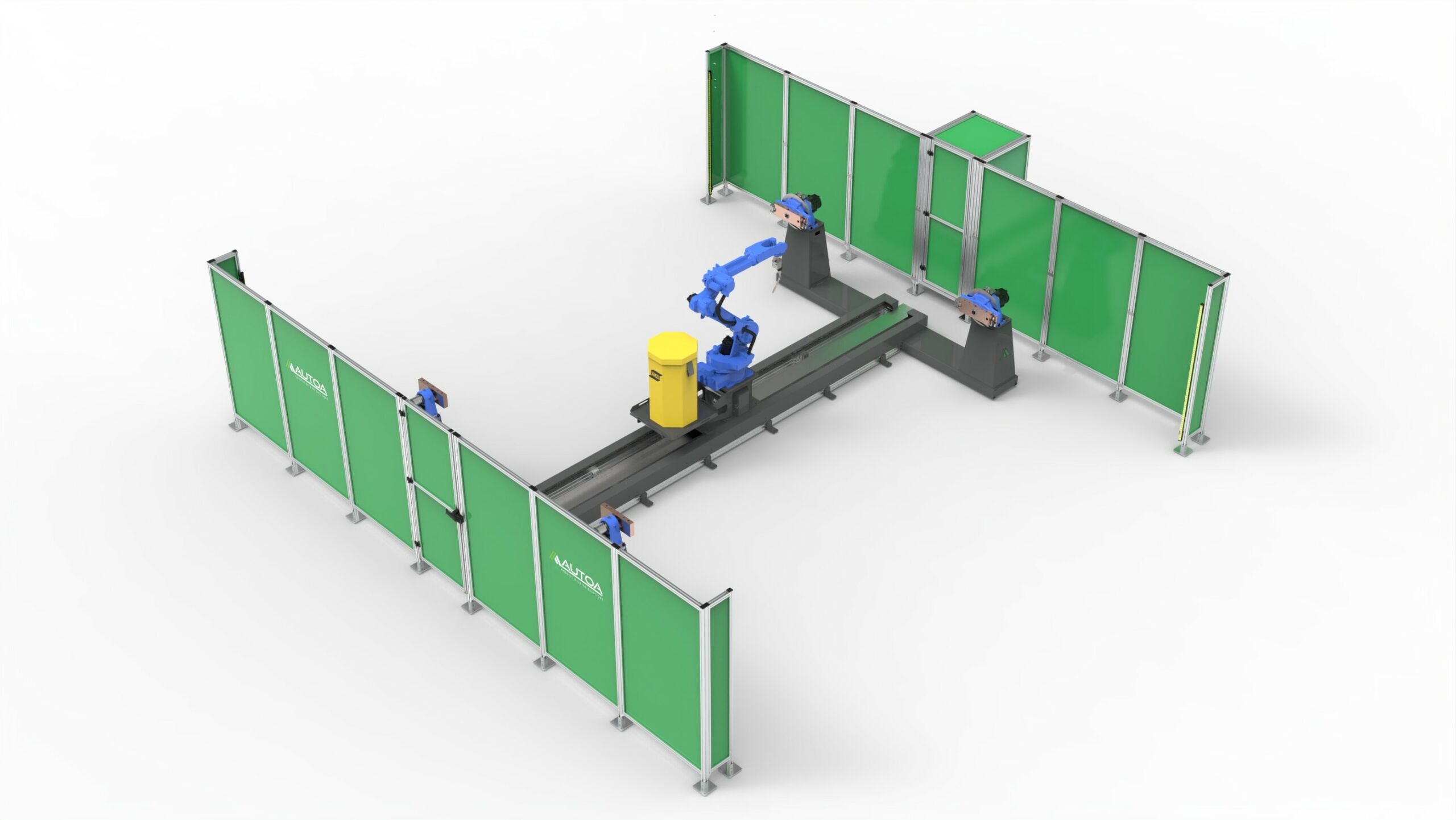

S-4800 Cell

The Autoa S-4800 robot welding cell is a highly efficient workcell designed for maximum throughput. Featuring a robot slider track, which serves as an additional axis in the dual-workstation cell, the S-4800 enables coordinated motion across eight axis; between the robot and positioned part, ensuring speed and efficiency.

Above: S-4800 cell shown without internal zone guarding.

Above: S-4800 cell shown with internal zone guarding.

S-6000 Cell

The Autoa S-6000 robot welding cell is a highly efficient workcell designed for maximum throughput. Featuring a robot slider track, which serves as an additional axis in the dual-workstation cell, the S-6000 enables coordinated motion across eight axis; between the robot and positioned part, ensuring speed and efficiency.

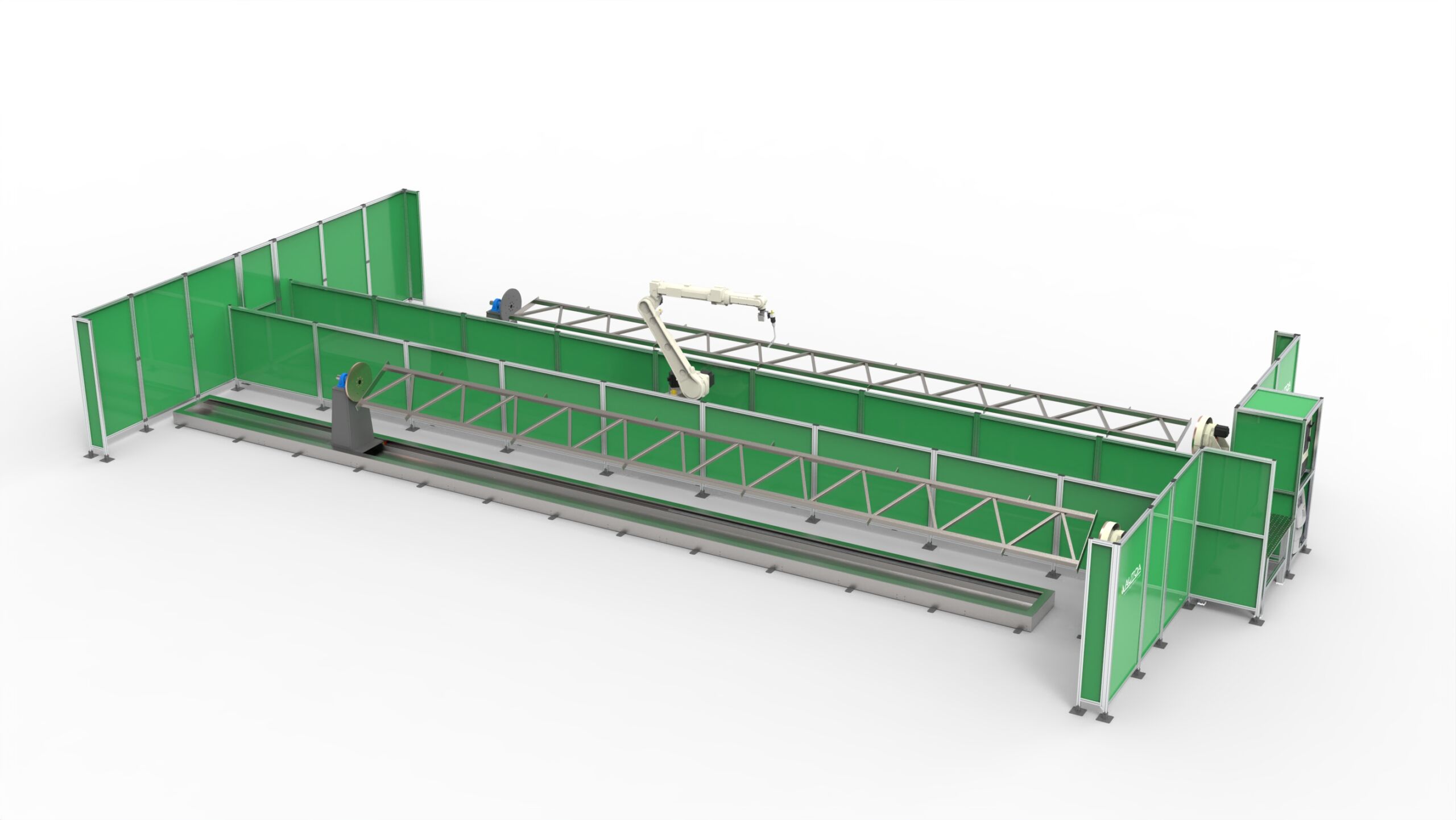

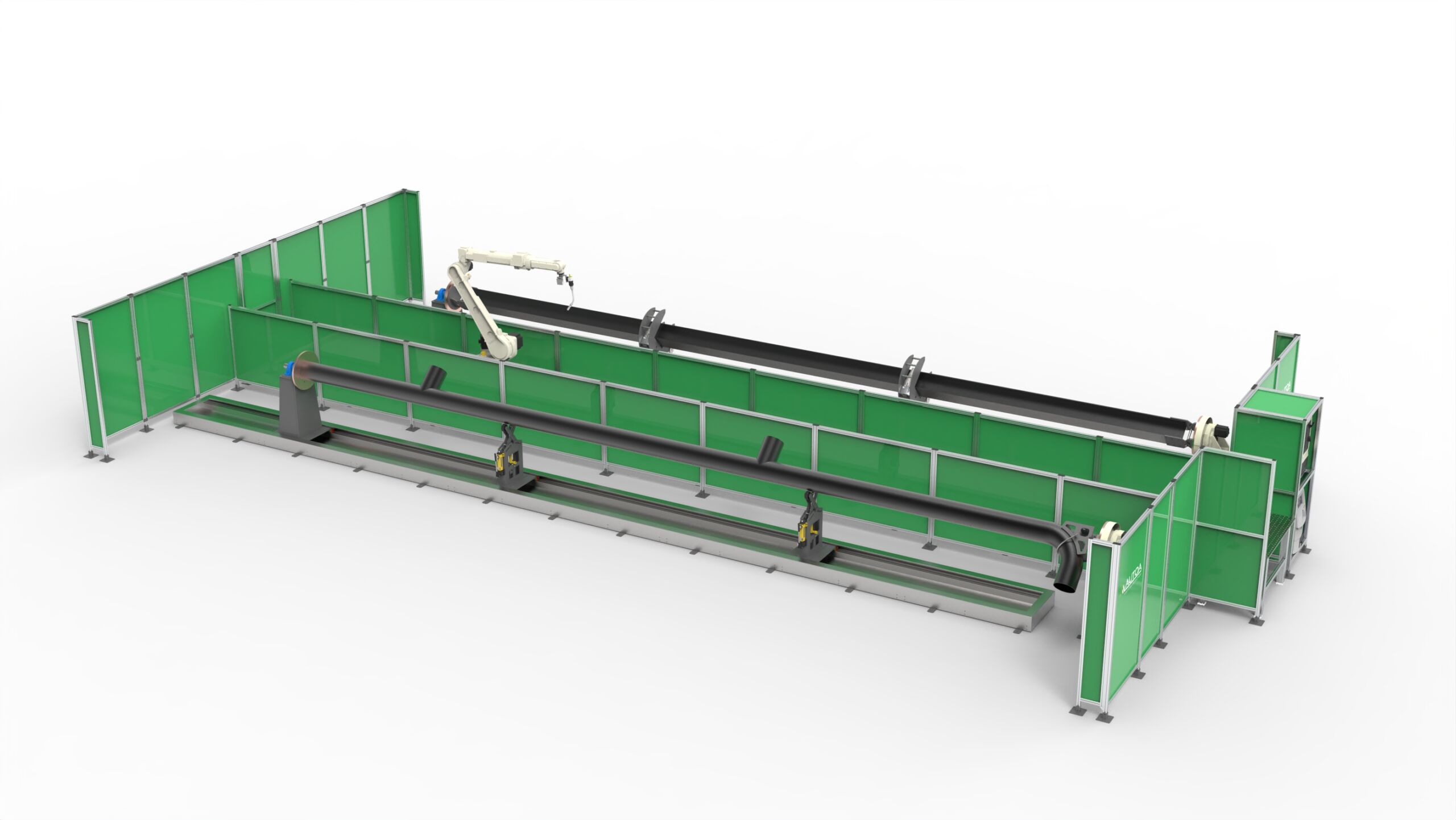

S-12000 Cell

The Autoa S-12000 robot welding cell is a highly efficient workcell designed for maximum throughput. Featuring a robot slider track, which serves as an additional axis in the dual-workstation cell. The S-12000 cell is the perfect welding cell for truss, pipe, or beam manufacturing – setting it apart as the sole robot welding cell on the market capable of handling a diverse range of welding tasks.

Above: S-12000 Cell for Open Web Truss Welding

Above: S-12000 Cell for Pipe Word Welding

AUTOA AI PATH PLANNING SOFTWARE

Introducing a New Era of Precision and Efficiency: Autoa’s AI Path Planning Software

Autoa’s AI path planning software represents a paradigm shift in the welding industry. Developed by Autoline, this proprietary software combines the power of artificial intelligence and machine learning to redefine welding tasks, introducing a new era of efficiency and precision.

By analysing a multitude of variables, the software swiftly determines the most effective welding path for each unique task, with a focus on achieving consistent high-quality welds while maximising productivity.

ANZRA Robotics Academy

ANZRA is New Zealand’s first and leading dedicated Robotic Academy, committed to providing outstanding robotic education and training to help individuals excel in their robotic careers in New Zealand and Australia.

Autoa robot welding cells qualify for a lifetime discount for robot training at the ANZRA Robotics Academy.