Training and Preparation is Key to Making the most out of Welding Robots

Customer: Anglo Engineering

Supplier: OTC Daihen by Autoline

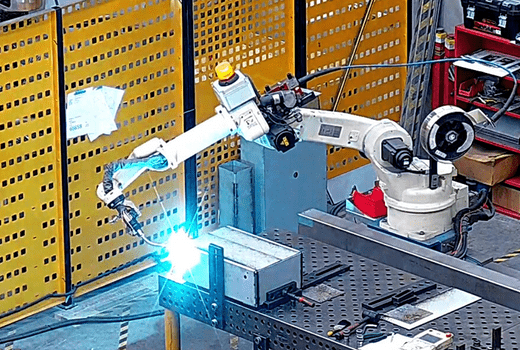

After a rocky start learning to correctly program Autoline’s robotic welder, Auckland-based Anglo Engineering are reaping the rewards of their investment.

The world-class sheet metal component manufacturer has been using Autoline robot welders since late 2018.

Anglo Engineering’s special projects manager Cy says the company decided to invest in a DAIHEN robotic welder to reduce welding and grinding time.

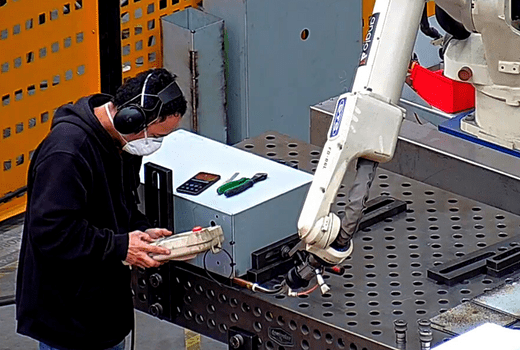

While they got the robot up and running relatively quickly, understanding the limitations of the machine and how to overcome them was a challenge, Cy says.

“We struggled to achieve consistent welding quality due to our inability to overcome the variation in the fabrication process,” he says.

“You could say we learned the hard way, the secret to using robots for most tasks is accuracy of parts and fixturing, while it was frustrating at the time, they were good lessons learned and now we are reaping the reward.”

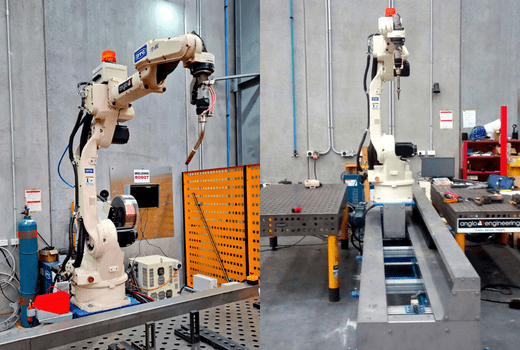

While integrating robots into the production line is always going to be a learning curve, doing the groundwork, the right training, getting the right personnel on board and understanding how robotic welders differ from manual welding was key to a smoother transition, he says.

“In hindsight we had unrealistic expectations regarding skill level required to program and operate the robot.

“Now with lessons learned and additional training we are consistently welding long seams (1.5M) using Cu/Si wire at 150cm per minute,” he adds. “And because of the faster welding time, the total amount of heat transfer to the parts results in negligible distortion.

“This is having a big impact on our ability to reduce cycle times and make consistent quality welds.”