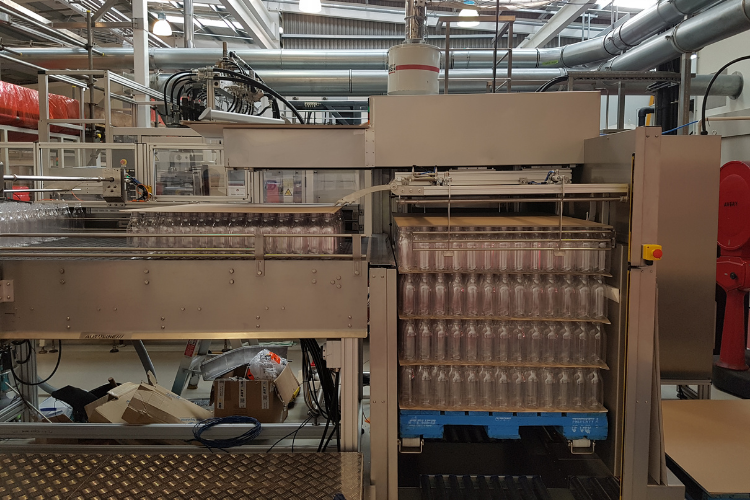

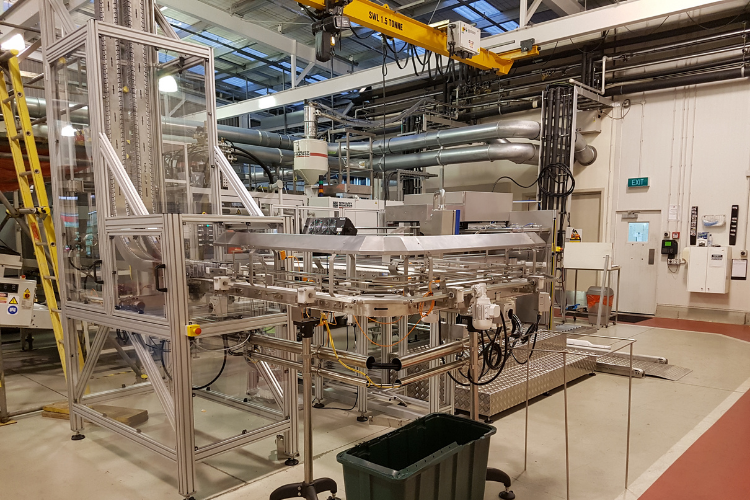

Depalletiser and Bottling Line Conveyor System

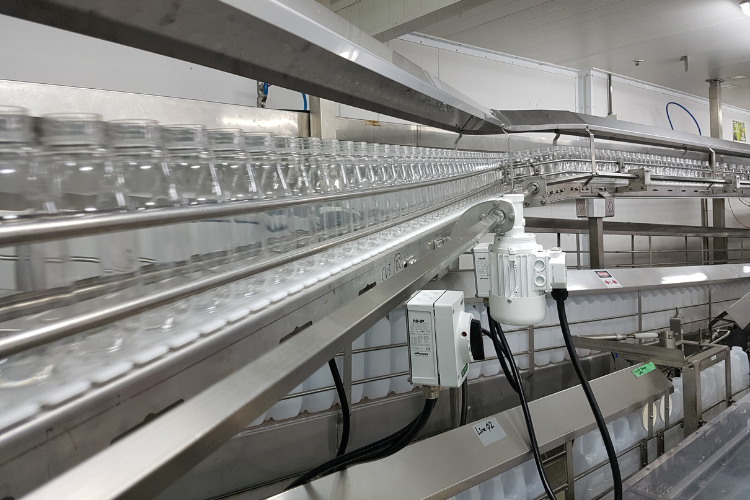

Depalletisers and bottling line conveyor systems work hand-in-hand to automate and streamline the beverage production process. The depalletizer acts as the unsung hero, efficiently removing empty bottles from incoming pallets, often at speeds exceeding 1000 bottles per minute. These bottles are then gently deposited onto the conveyor system, which acts as the circulatory network of the bottling line. This network of interconnected belts transports the bottles through various stages, from rinsing and filling to labeling and capping, ensuring a smooth and uninterrupted flow of production. Together, these systems orchestrate a well-oiled ballet, maximizing efficiency and minimizing manual labour in the bottling process.

Equipment:

- Custom designed depalletiser suitable for HDPE & PET bottles

- Line speed 110 bottles per minute

- 8 different bottle sizes and types, fully automatic side guide width changing system

- 90m total of the conveying system

- 2x side gripper elevators and lowerators

- Custom recipe system via HMI to enable the operator to simply select recipes dynamically

- Conveyor ramp up and down to reduce line pressure instead of pneumatic line breaks

Date: April 2017

Brand: Autoline Automation

Application: Empty bottle conveying