Project Description

Robotic Assembly and Handling

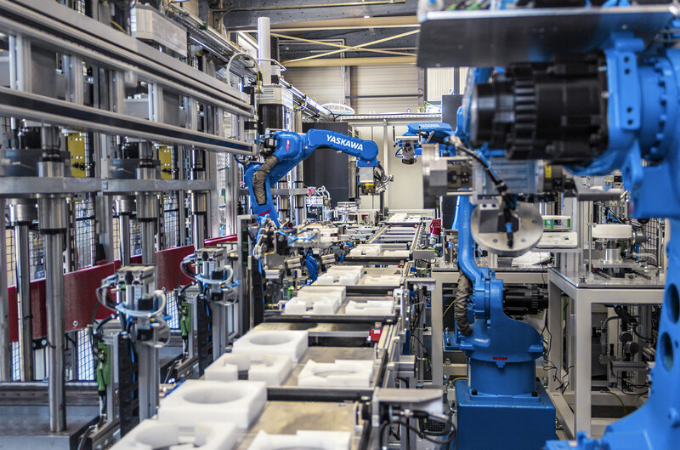

Materials Handling

Material handling robots are used to move, feed or disengage parts or tools to or from a specific location, or to transfer parts from one machine to another. Manufacturing companies all over the world integrate material handling robots into their systems due to their speed, precision and cost-effectiveness. Compared to manual material handling, they also provide a consistent standard of quality and a high level of repeat accuracy.

Industrial robots, many of which feature vision technology or other equipment, relieve factory personnel from tedious and dull production line tasks, resulting in increased productivity and product quality.

The robots eliminate downtime, reduce labour costs and provide a high return on investment. They can also operate 24 hours a day all year round.

Press Brake Tending

Thanks to the modular program design and the gripper changeover system, the plant system implementation is very flexible and can be adapted to rapidly changing production requirements.

A sensor system ensures high quality and the required protection against machine failure, processing errors, waste etc., enabling identical handling for every workpiece. The plant variant is subject to the size and weight of the component. Robots from the complete MOTOMAN ES and MOTOMAN HP series are selected accordingly.

Benefits:

- Improved efficiency

- Suitable for small batch quantities due to MOTOMAN MotoBend offline programming software

- Reduced dependence on manual labour

Assembly

Industrial robots may feature vision technology or other equipment, relieving factory personnel from tedious and dull production line tasks and resulting in increased productivity and product quality.

The robots eliminate downtime and provide a high return on investment. They can also operate 24 hours a day all year round.