Robots’ Consistency and Quality Provide Savings

Customer: Adept

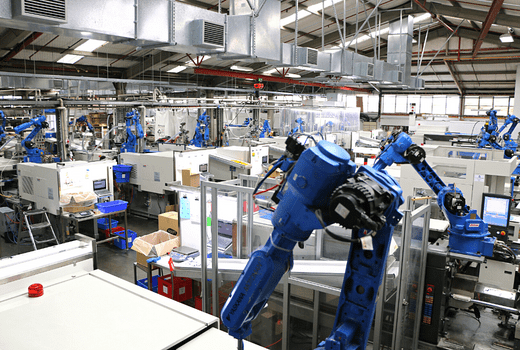

Supplier: Yaskawa by Autoline

Integrating 6-axis robots into production resulted in labour saving, greater consistency, and higher quality, says Adept general manager Stuart Rodden.

Adept is a world leader in the product development and manufacturing industry, specializing in high precision plastic injection moulding.

Adept works with many businesses from startups, to major brands, research institutes and the medical and meat processing industries to create cost-effective solutions using its state of the art plastic injection moulding facility, which ensures products are manufactured to international quality standards.

Stuart says switching to robotics about 15 years ago was a natural progression for the company, which is always looking to innovate and improve its products and services.

“After making the switch to robotics, we found we could produce a higher volume with a lot less people, at a consistently high level of quality, rather than the inevitable variation you get with people on the production line,” he says.

The company uses Autoline’s 6-axis robots, which have a high level of flexibility, reach, and strength, making them ideal for performing complex functions.

The robots have replaced some machine operators over time, however they now employ a greater proportion of engineers and technicians to program the robots and set them up, he says.

“Autoline has been good to work with over the years,” Stuart says. “Our robots come in a box and are set up by our own staff, so we don’t have to rely on anyone off-site, however it’s been good having Autoline’s support when needed.”