Robot Solutions For Every Industry And Application

Autoline is New Zealand's leading robotics company, specialising in automation and robotic systems for a wide range of industrial applications in the manufacturing industry.

We offer high-quality robotic solutions to help our clients increase productivity and reduce production costs. Which in return helps our customers to build a strong competitive advantage in their industries and markets. Our industrial robotic automation solutions are custom designed and built to meet the requirements of today’s highly competitive manufacturing industry. We represent world-leading robot brands bringing the most advanced robotic solutions and latest robotic technology and innovations to New Zealand.

We offer high-quality robotic solutions to help our clients increase productivity and reduce production costs. Which in return helps our customers to build a strong competitive advantage in their industries and markets. Our industrial robotic automation solutions are custom designed and built to meet the requirements of today’s highly competitive manufacturing industry. We represent world-leading robot brands bringing the most advanced robotic solutions and latest robotic technology and innovations to New Zealand.

With over 35 years of experience in industrial robotics and over 200 robots commissioned and installed globally, we support our valued customers with world-leading technology and excellent technical support and service.

We position ourselves as your partner for robotics and automation, taking a collaborative approach. Our team can assist you in building a business case that demonstrates real savings through improving the production process, investment of capital equipment and staff training.

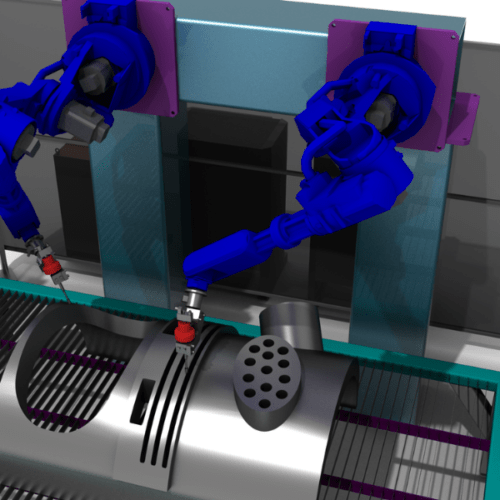

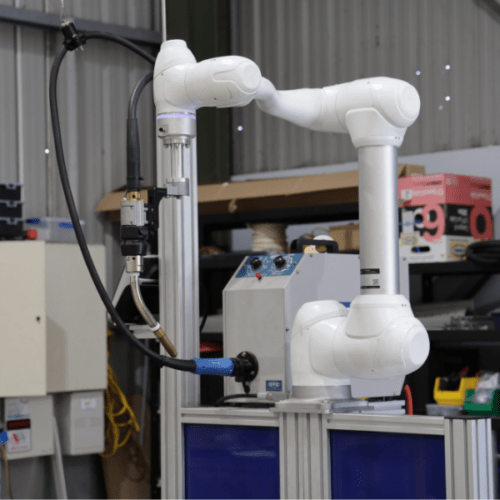

We provide robotic and automation solutions for applications such as robot welding, palletising, materials handling, assembly, and machine tending for many different industries in New Zealand. Typical robot applications are simple and repetitive tasks that required dedicated resources to perform.

The benefits of robotic automation are:

Robotics increase productivity and reduce costs

We position ourselves as your partner for robotics and automation, taking a collaborative approach. Our team can assist you in building a business case that demonstrates real savings through improving the production process, investment of capital equipment and staff training.

We provide robotic and automation solutions for applications such as robot welding, palletising, materials handling, assembly, and machine tending for many different industries in New Zealand. Typical robot applications are simple and repetitive tasks that required dedicated resources to perform.

The benefits of robotic automation are:

Robotics increase productivity and reduce costs

- - Simple tasks are performed more quickly versus manual processes.

- - Robots free-up your skilled workforce to perform more complex tasks, making better use of time and money.

- - Robotics provides consistent and predictable productivity that reduces management oversight. Common factors that jeopardize timelines (retraining, shift changes, sick leave, and turnover) have less impact on your operation.

- - Up to 4 robots can be added to a single controller to multiply the speed/scale of a task.

- - A robot can be programmed to perform multiple jobs in a single setup – easing transition time, training, and space requirements.

- - Programming / reprogramming a robot is typically less time than prepping a conventional setup. Robot programming has become easier than in the past, and programmers can be trained by Autoline robot technicians in-house.

- - Software and perception technology has expanded robotic capabilities in recent years – allowing them to perform more tasks than previously possible.

- - Robotic movements are consistent, focused, and precise – often within 0.5 mm of repeatable accuracy.

- - Avoid increased productivity loss and re-work that tends to happen late in a shift or work week due to fatigue.

- - Quality scales up without the challenges of finding skilled workers to maintain it.

- - The capital expense can be easily financed and provide tax advantages.

- - Through an in-house specialist or robotics partner, ongoing programming and maintenance costs are lower than training and maintaining equivalent staff.

- - The life cycle of a robot can last years beyond its break-even threshold, then can be remanufactured for a “second life.”

- - Unlike other forms of automation, robots can be repurposed for a broad range of applications.

- - Increased margins through predictable, high-quality production give you the leverage needed to stay competitive, retain customers and win new business.