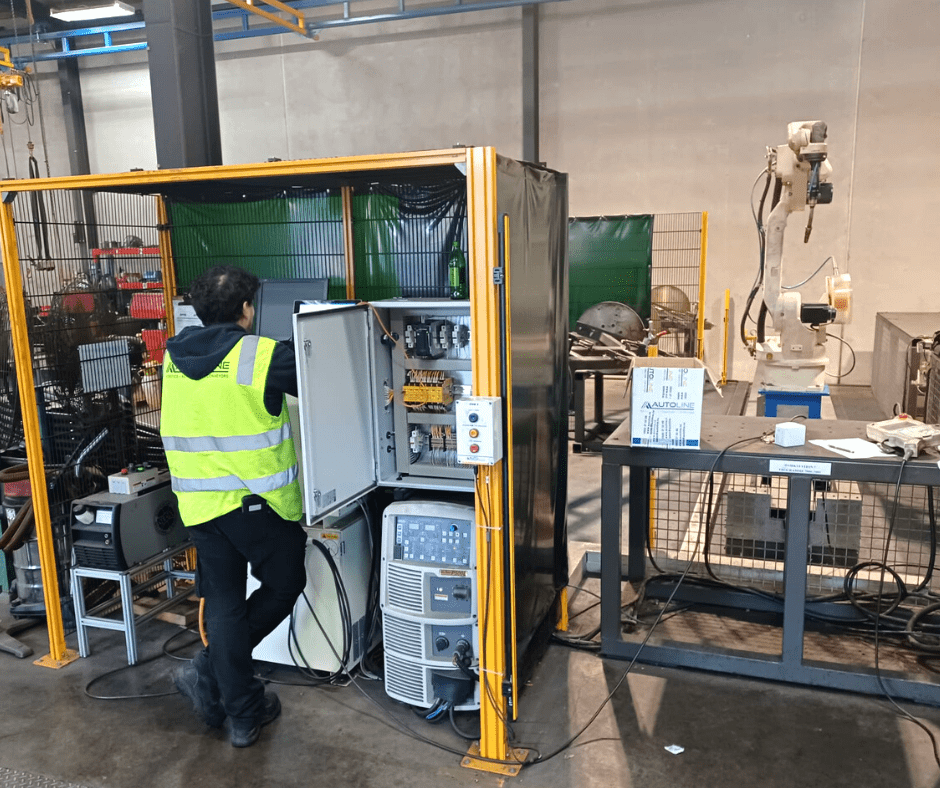

Robot Servicing and Maintenance

Our guarantee of expert service goes beyond delivering industry-leading robotic and automation solutions customised to your specific needs. After your automation equipment is installed, we will continue to provide dedicated support and ongoing service to ensure maximum robot performance and return on investment over the life of your asset.

Autolines in-house skilled robot technicians are trained service and application engineers with years of experience working with Yaskawa, OTC Daihen, and Doosan equipment. We currently service and maintain over 200 robots operating throughout New Zealand. These include successful installations of robotic applications such as MIG/MAG welding of ferrous and nonferrous metals, plasma welding and cutting, routing of fiberglass and plastics, materials handling and packaging, palletizing, machine and press brake tending applications.

Our Robot Maintenance Guide:

The manufacturer’s (Yaskawa and OTC Daihen) recommendation is to service a robot every 2 years or 6000 servo hours. A typical service consists of full lubrication and replacement of all encoder backup batteries. Replacement of encoder backup batteries is essential to maintain correct encoder positions as these cannot be restored with a backup of data and if allowed to fully discharge, it can involve extensive reprogramming of your robot and an urgent service call out.