YOUR ONE STOP ROBOT PALLETISING SHOP

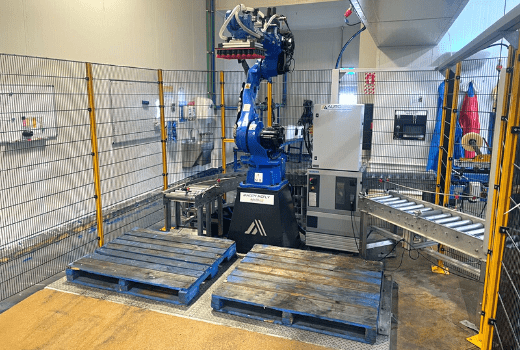

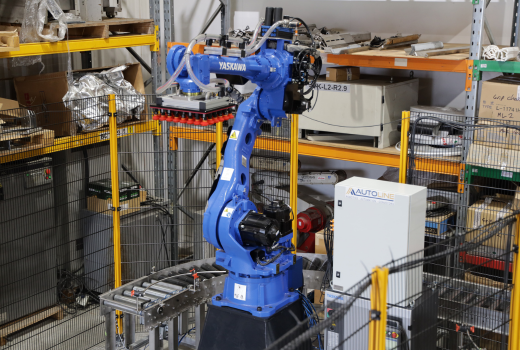

In our advanced robotic palletising systems at Autoline, products seamlessly flow into the palletising cell through an efficient infeed conveyor. Skillfully programmed, the robot precisely stacks items onto the pallet in predefined patterns as they enter.

Our robotic palletising systems provide unparalleled flexibility, capable of handling single or multiple production lines concurrently. This dual adaptability not only reduces costs but also significantly amplifies productivity and manufacturing capacity. Palletising cells are intelligently configured with features such as pallet dispensers, slip sheet insertion tools, and shrink-wrapping stations, ensuring a fully automated palletisation process.

Palletising stands out as one of the fastest-growing robotic applications, offering superior speed and safety compared to manual methods. Our robotic solutions are not only flexible but also space-saving, outperforming fixed machinery alternatives. With certified food-grade lubricants as standard, our palletising robots find applications across diverse industries, including food and beverage, warehouse and distribution, and industrial products. Elevate your efficiency with Autoline’s cutting-edge robotic palletising solutions.

Key Benefits of Robotic Palletising

- Increase in Productivity and Throughput.

- Improved Health and Safety for employees by minimising continuous lifting of products.

- Improved and Consistent Quality.

- Reduced Dependence on Manual Labour.

- Labour Savings.

- Ability to Work Around-the-Clock.

- Lower Production Costs.

- Reduced Damage to boxes and products.

INDUSTRIAL ROBOT PALLETISERS

Industrial robot palletising is an automated system used in manufacturing and logistics to efficiently arrange products onto pallets for storage or shipping. In this process, products are fed into a designated area, known as the palletising cell, where an industrial robot equipped with specialized grippers or end of arm tooling carefully stacks them onto a pallet following a predetermined pattern.

COLLABORATIVE ROBOT PALLETISERS

Collaborative robot palletising involves the use of specialised robots designed to work alongside human operators in palletising tasks. Unlike traditional industrial robots, these collaborative robots, or cobots, are equipped with advanced sensors and safety features that allow them to operate safely in shared workspaces without the need for safety barriers.

World Leading Robot Brands

Autoline is proud to represent multiple world-leading robotics brands in New Zealand that provide numerous options and systems for robotic palletising applications.

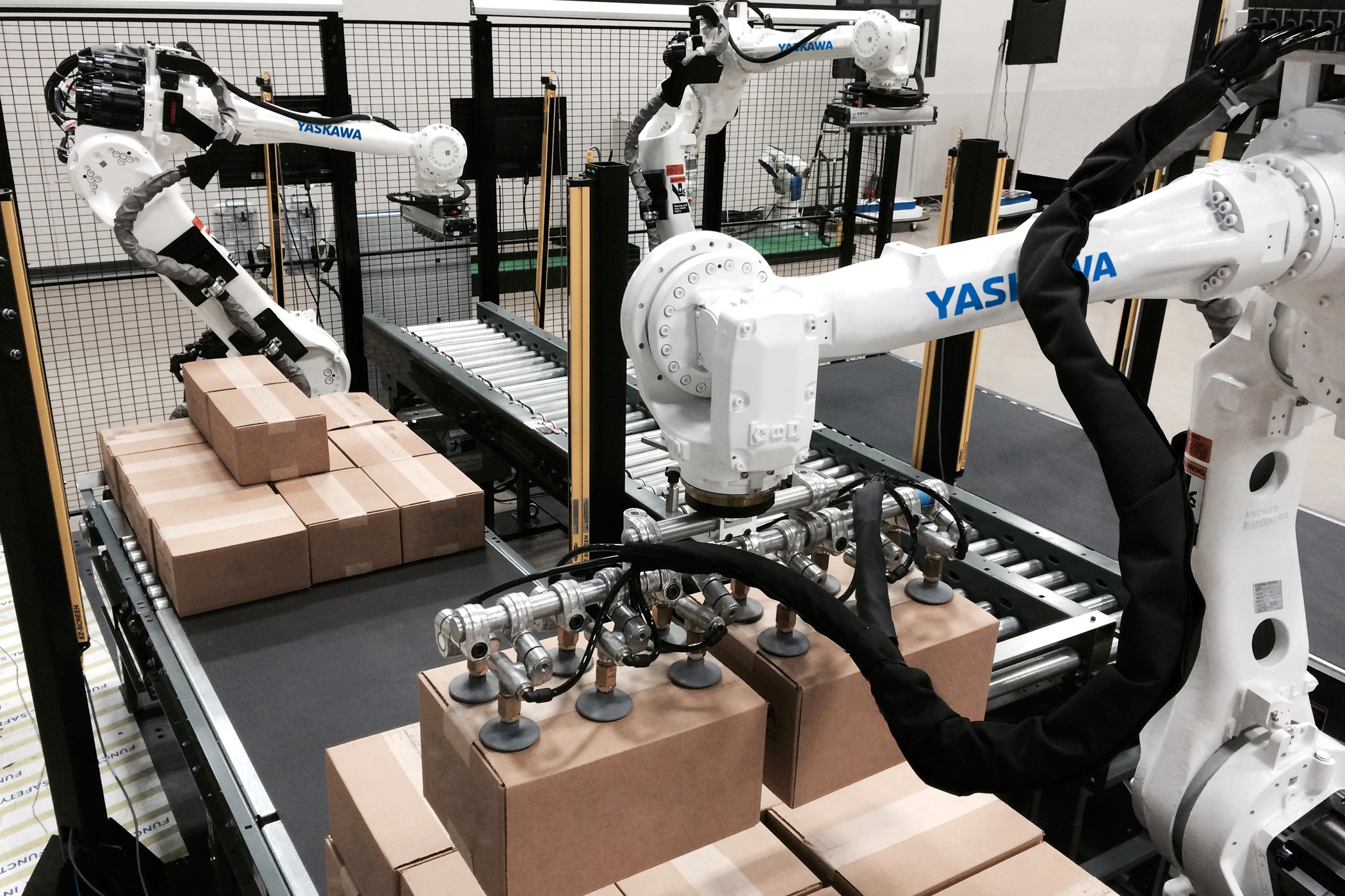

Yaskawa Motoman offers manufacturers a wide range of robotic solutions for palletising and depalletising. Yaskawa robotic palletizers are designed for speed, durability and cost-savings – enhanced by application-enabling software and vision capabilities to help you to tackle simple to complex palletising jobs. The palletising robots range from 50 kg to 800 kg payload with 4-6 axes of articulation. With this wide range of payload capacity, it’s your choice to pick single-case or an entire layer for stacking and breaking down pallet loads. All of Yaskawa palletizer robot models are compatible with the Yaskawa MLX package, allowing you to program them and run Yaskawa’s PalletSolver software directly from your PLC.

Doosan have a H Series range of collaborative robots which are the most heaviest payload cobot on the market. With an outstanding 25kg payload and 6 torque sensors, brings a safe work environment for a palletising application. The Doosan H Series Cobots are in a class of their own. Other cobot brands like Universal Robot do not have compatible specifications. The UR20 is Universal Robots’ newest model cobot and this has a 20kg payload and a 1700mm reach. This model is the heaviest payload available at Universal Robots. It still falls short of the Doosan H-Series 25kg payload capacity. Universal Robots has a lower payload and reach range. UR offers a range of 500mm to 1700mm, compared to the Doosan H Series 1500mm to 1700mm reach, the Doosan Cobots is a clear winner.

Robotic Palletising Enquiry

Talk to the Robotic Palletising experts at Autoline to discuss your current palletising process and learn how a robot palletising system can help you reduce downtime and increase your productivity, giving you a competitive edge in your industry.