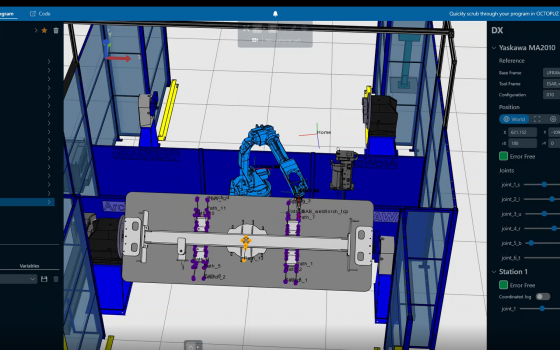

Seamlessly design, simulate and optimise your robot’s processes offline

Offline robot programming is a cutting-edge method that revolutionises industrial automation by enabling engineers to program robotic systems in a virtual environment, separate from the actual production floor. Through specialized software and simulations, intricate robot movements and tasks are meticulously planned and optimized without disrupting ongoing operations. This approach offers numerous advantages, including enhanced time efficiency as programming tasks can be completed concurrently with production, cost savings by minimizing machine idle time, and risk reduction through comprehensive hazard identification prior to implementation. Moreover, offline programming fosters flexibility, allowing for swift adjustments and iterations to meet evolving production needs without interrupting workflow. By optimizing resource allocation and ensuring precise robot movements, offline programming ultimately drives higher quality outputs while providing engineers with valuable opportunities for skill development in a controlled setting.

Unlock the potential of robotics with Autoline’s innovative software options, streamlining your manufacturing operations for unparalleled productivity.

Offline Robot programming key benefits

-

Time Efficiency:

Offline robot programming allows for simultaneous programming and operation, reducing downtime on the production floor.

- Cost Savings: By minimizing machine idle time, offline programming helps maximize the utilization of resources and reduces production costs.

- Risk Reduction: Simulating robot operations in a virtual environment helps identify potential issues and hazards before implementation, enhancing safety.

- Flexibility: Programming can be done offline, independent of the production schedule, enabling quick adjustments and iterations without disrupting ongoing operations.

- Resource Optimization: It optimizes resource allocation by allowing engineers to work on programming tasks without occupying physical robot assets.

- Quality Improvement: With thorough simulation and testing, offline programming ensures precise and accurate robot movements, leading to higher-quality outputs.

- Skill Development: Engineers can enhance their programming skills in a safe, controlled environment without affecting live production processes.