Automate Your Machine Tending Processes

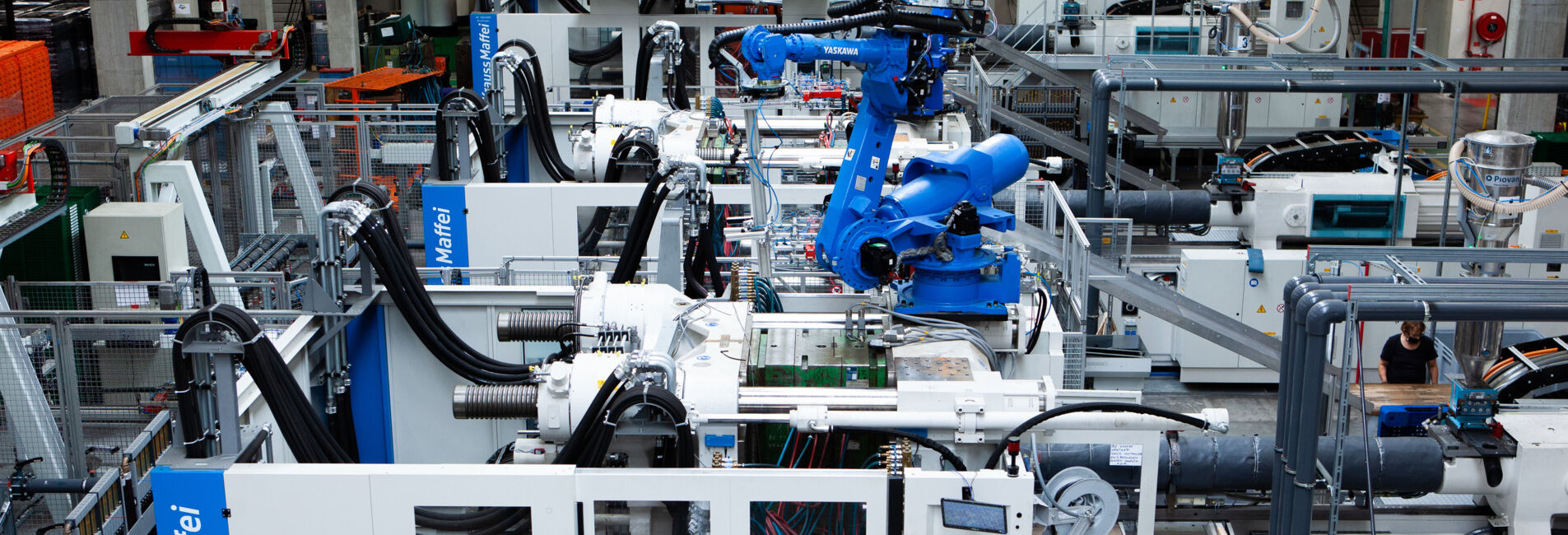

Robotic machine tending (CNC Machine Automation) is the process of using a robot system to automatically load and unload a production machine. This can be any kind of machine, most common are CNC machine tools or Injection molding machines & Special purpose machines.

Machine Tending Robots can relieve qualified CNC Operators and Programmers from loading/unloading operations. Robotic Automation enables Industrial Machines to operate without human intervention, running unmanned over a whole shift or overnight, tirelessly and consistently for ‘lights out’ production. Other benefits include higher machine utilization, freeing the worker up for multi-machine operation, programming or downstream processes, resulting in higher and more stable overall production rates.

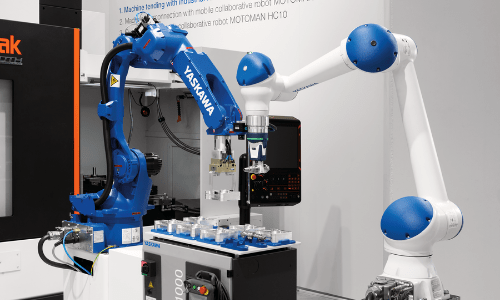

With years of project collaboration with machine OEMs, robotic integrators and end customers make Yaskawa Motoman a valuable resource for simple and effective robotic machine tending options.

Yaskawa Robots for Machine Tending

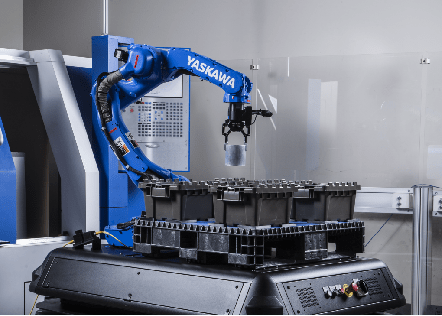

In many machine tending applications, the robot is exposed to chips, dirt and aggressive coolants. IP67-protected versions of the GP Series Robots and HC10DT-IP67 / HC20DT cobots are available are perfectly designed for those rough jobs, being well protected against corrosive and warm steamy environments.

Machine Tending with GP Series Industrial Robots

As machine tool size, design and loading concepts may vary a lot, robotic arms can be arranged in many ways. Small robots for small workpieces, like the MotoMini, GP7 or GP8 can be built into the machine housing (exposed to the atmosphere inside the machine), while larger robots are positioned in front of the slider door.

Yaskawa Motoman robot manipulators are perfect for machine tending due to their slim wrist design and narrow footprint. They provide the required repeatability which you need. They support any Multi-Gripper you can find, gripper media supply cabling is guided inside the manipulator arm or through the hollow wrist in most of the cases. High IP65/67 rated versions are available for heavy duty applications when the robot is exposed to cooling liquid, dust or chips – robots can be cleaned easily.

Robotic Automation for CNC Turning, Milling, Drilling and Grinding Machines

Machine tending in the metalworking industry is commonplace. Whether the process is turning, milling, grinding, drilling, CNC controlled or not, a robot can precisely load and unload parts, removing the inconsistencies of a manual process. Robotic machine tending is not limited to metals; it offers benefits to manufacturers also working with polymers, ceramics and composites. Double grippers are broadly used, allowing to load raw parts and unload finished parts within the same motion sequence.

Robotic Machine Tending Key Benefits

- Increase in Productivity and Output

- Increased Payload Abilities

- Reduced Waste of Materials and Parts from Manual Error

- Improved and Consistent Quality

- Reduced Dependence on Manual Labour

- Labour and Time Savings

- Ability to Handle Dangerous Materials/Parts

- Ability to Work Around-the-Clock

- Improved Employee Ergonomics and Health and Safety

- Increased Efficiency in Production