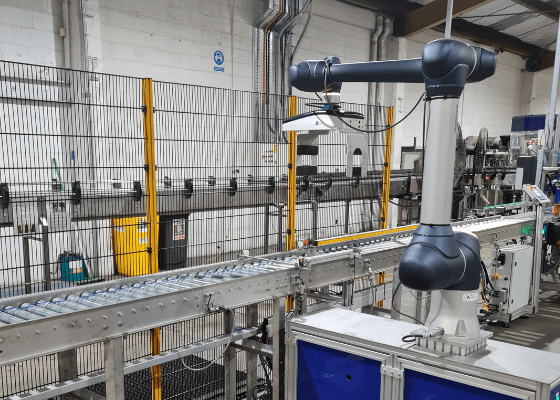

Collaborative robot palletising involves the use of specialised robots designed to work alongside human operators in palletising tasks. Unlike traditional industrial robots, these collaborative robots, or cobots, are equipped with advanced sensors and safety features that allow them to operate safely in shared workspaces without the need for safety barriers.

In collaborative robot palletising, the cobot is programmed to pick up and stack products onto pallets, working in tandem with human workers. These robots are designed to be intuitive and user-friendly, allowing for easy programming and quick deployment. They can adapt to different product sizes and palletizing patterns, providing a high level of flexibility.

Collaborative robot palletising brings several benefits to the manufacturing process. It enhances efficiency by automating repetitive and physically demanding tasks, allowing human workers to focus on more complex aspects of the operation. It also improves safety by reducing the risk of workplace injuries associated with manual palletising. Overall, collaborative robot palletising represents a significant advancement in palletizing technology, offering a harmonious blend of human expertise and robotic precision to achieve optimal results in palletising applications.

COLLABORATIVE ROBOT Palletising BY AUTOLINE

Autoline embraces the dynamism of the food and beverage industry by specializing in Collaborative Robot Palletising. In this competitive landscape, cobots emerge as versatile partners, bringing efficiency and flexibility to palletising processes. These adaptable assistants seamlessly collaborate with human operators, safely handling tasks like precise stacking onto pallets.

Designed for agility and dexterity, cobots boast user-friendly interfaces and advanced sensors, making them ideal for dynamic industries like food and beverage. In an environment where change is constant and customization is crucial, cobots shine by effortlessly adapting to varying packaging sizes and configurations. Their ability to enhance productivity and ensure consistent quality positions cobots as indispensable allies in the ever-evolving food and beverage sector. Autoline’s commitment to this innovative collaboration underscores its dedication to meeting industry demands.

AUTO-CoPaL

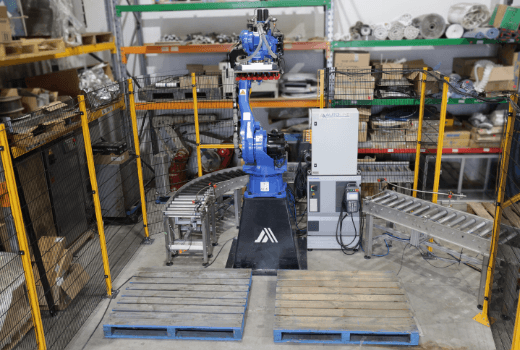

A flexible palletising solution that delivers the reliability of an industrial palletising system.

Optimise your end-of-line productivity by automating repetitive tasks with the Auto-CoPal, a cost-effective and flexible palletising solution. A collaborative robot palletiser combines a high payload cobot and our revolutionary palletising robot base to provide a flexible solution that will streamline your packaging process.

The Auto-CoPal is a configuration of reliable and proven technology with a Doosan Collaborative Robot and OnRobot End-of-Arm Tooling. Heavy-duty collaborative robot palletising is now possible with the Doosan H Series model cobots which have the heaviest payload available on the market, bringing a safe work environment for heavy object stacking and palletising.

The high payload cobot features a 25kg payload, this means the Auto-CoPal palletising system can handle heavy boxes that are considered a health and safety risk for humans to stack. With the flexibility to palletise single or multiple production lines simultaneously. This dual adaption reduces costs while also increasing your productivity and manufacturing capacity.

Palletising collaborative robots offer the ability to lift heavy payloads at a good speed, reducing cycle times, increasing the stacking rate of boxes, and achieving greater dynamic performance.

KEY BENEFITS OF THE AUTO-COPAL

-

Compact designed end of line packing solution with smart safety-enabled for operator protection.

- OnRobot offers a wide range of end-of-arm tooling products to optimise your palletising application.

- The Doosan Cockpit allows for easy programming of the robot arm by simply guiding it by hand.

- Palletise two pallets measuring 1200mm x 1000mm on each side, up to 2000mm high.

- Offline programming software enables programming of various pallet configurations.

- Multiple boxes can be picked in one movement too increase speed.

- Capability to automatically insert layer boards.

- Single-phase supply and no air required.

- Payload up to 20kg

COBOT VS INDUSTRIAL ROBOT PALLETISING

When deciding between cobot and industrial palletisers and selecting the right robotic automation system for your production line, four main characteristics should be considered. Collaborative Robot Palletising, or cobot palletising, offers notable flexibility and safety in collaborative environments. Cobots are adept at switching between various palletising tasks, accommodating diverse packaging formats and sizes. While industrial robots excel in heavy-duty operations, ensuring consistent performance without breaks, cobots shine in their ability to adapt to dynamic environments. Although industrial robots may be preferred for high-volume and heavyweight palletising needs due to their unmatched efficiency and precision, cobot palletising proves superior in terms of flexibility and safety in collaborative settings, aligning with the evolving needs of modern production lines.

1. Payload

Number one is how much weight do you require the robot to lift?

Collaborative robots, or cobots, defy the perception that industrial robots inherently outclass them in palletising tasks. Doosan’s H-Series cobots, a heavyweight contender, proudly boasts a remarkable 25kg payload, challenging the notion that industrial robots hold a monopoly on superior payloads. The argument favoring industrial robots for high payloads is debunked by the robust capabilities of cobots, especially evident in Doosan’s H-Series. The once perceived limitation of a 25kg threshold for cobots is now surpassed by innovative designs. In assessing palletising solutions, cobot palletisers emerge as formidable options, delivering efficiency, flexibility, and substantial payload capacities that perfectly align with the demands of modern manufacturing.

2. Reach

The next consideration is reach, how high do you need to stack your boxes on the pallet?

The H Series models from Doosan have a reach of 1500mm and 1700mm which is outstanding flexibility for the powerful payload of 20kg and 25kg! Once your required reach is above the maximum reach for the collaborative robot arm, it may be difficult for a collaborative robot to meet your needs. In this case, industrial robots have larger reaches and would likely suit the application better.

3. Workspace

The third consideration is what space do you have available on your production floor?

A collaborative robot palletiser has a smaller footprint than an industrial robot palletiser system and takes up less physical space. Cobot palletisers also don’t require any guarding due to the industry’s best collision sensitivity powered by 6 torque force sensors, this allows humans to work alongside the collaborative robot safely. Whereas Industrial Robots require full safety guarding and sensing around the perimeter of the footprint to protect humans. It depends on the layout of your production line and floor space you have to determine whether an industrial robot or a collaborative robot would suit your palletising application best.

4. Speed

Lastly how fast do you require the robot to run per cycle?

Industrial robots and collaborative robots have similar cycle times, the reason that industrial robots can handle such high volumes is due to their higher payload capacity. Depending on the weight you are trying to lift, industrial robots can lift a whole layer of boxes or bags in a cycle whereas typically a collaborative robot only lifts one to two boxes at a time.

DOOSAN ROBOTICS

Doosan have a H Series range of collaborative robots which are the most heaviest payload cobot on the market. With an outstanding 25kg payload and 6 torque sensors, brings a safe work environment for a palletising application. The Doosan H Series Cobots are in a class of their own. Other cobot brands like Universal Robot do not have compatible specifications. The UR20 is Universal Robots’ newest model cobot and this has a 20kg payload and a 1700mm reach. This model is the heaviest payload available at Universal Robots. It still falls short of the Doosan H-Series 25kg payload capacity. Universal Robots has a lower payload and reach range. UR offers a range of 500mm to 1700mm, compared to the Doosan H Series 1500mm to 1700mm reach, the Doosan Cobots is a clear winner.

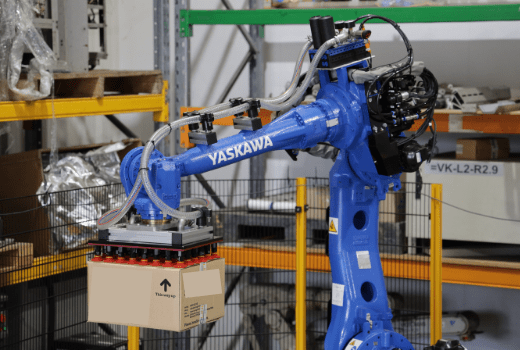

Yaskawa Robotics

Yaskawa Motoman offers manufacturers a wide range of robotic solutions for palletising and depalletising. Yaskawa robotic palletizers are designed for speed, durability and cost-savings – enhanced by application-enabling software and vision capabilities to help you to tackle simple to complex palletising jobs. The palletising robots range from 50 kg to 800 kg payload with 4-6 axes of articulation. With this wide range of payload capacity, it’s your choice to pick single-case or an entire layer for stacking and breaking down pallet loads. All of Yaskawa palletizer robot models are compatible with the Yaskawa MLX package, allowing you to program them and run Yaskawa’s PalletSolver software directly from your PLC.

Collaborative ROBOT Palletising ENQUIRY

Talk to the Robotic Palletising Experts at Autoline to discuss your current end of line process and find out how a collaborative robot palletising system can help you increase your profitability, giving you a competitive edge in your industry.