Industrial and Collaborative Robots

Yaskawa Motoman Industrial and Collaborative Robotics are industry-leading, high-speed with high-payloads and extended-reach making the applications for robotics endless. Yaskawa manufacture industrial robots, robot peripherals, robotic software and robotic workcells.

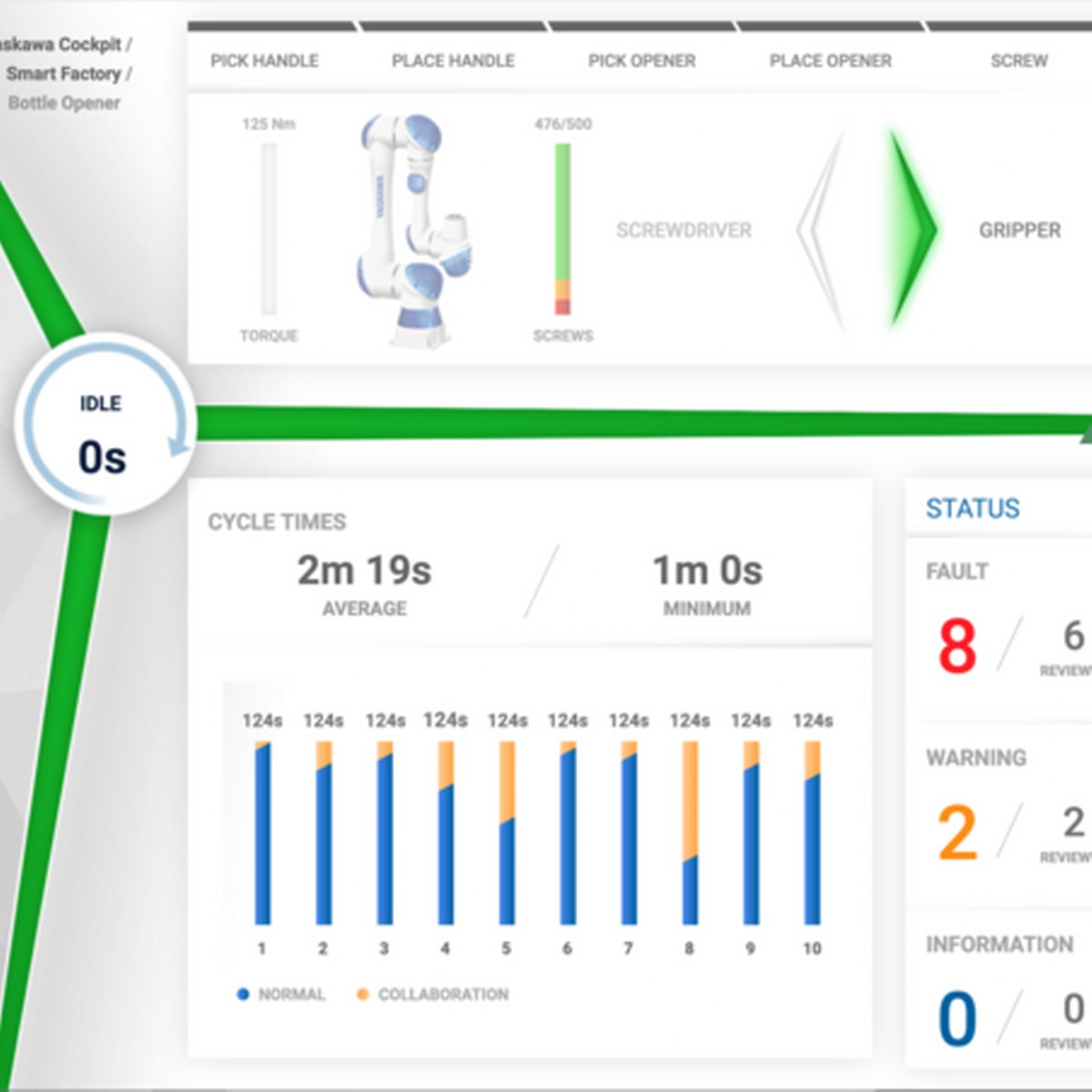

Typical results from robotic automation are; increased productivity from your labor force, increased workplace safety due to manual handling processes being carried out automatically. Plus reduction in waste, consumables and rework thorough consistency and increased profitability giving you a competitive edge in your industry. The operating speed and accuracy of Yaskawa Motoman robots reduces your cycle time and increase productivity.

Yaskawa in New Zealand

Autoline delivers industrial leading Yaskawa Motoman industrial and collaborative robots in New Zealand. We are able to offer manufacturers complete customised robotic systems to help increase productivity from your labour force, increase workplace safety due to manual handling processes being carried out automatically and reduce waste and rework through the consistent quality of production. All for a higher profitability in your business, a faster return on investment and a competitive edge in your industry.

We provide a wide range of Yaskawa robots solutions to improve your production capabilities as Motoman industrial robots include high-payload, high-speed, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots. With cutting-edge controllers, vision systems, peripherals and other best-in-class components, we can configure a solution tailored for your manufacturing needs.

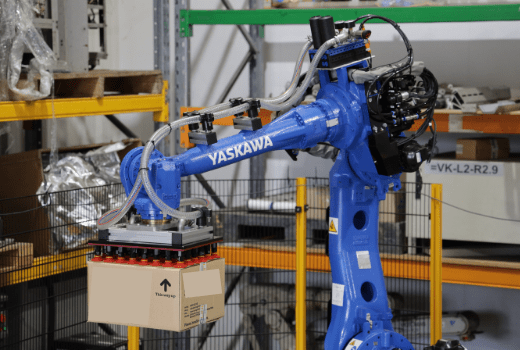

Yaskawa Motoman offers manufacturers a wide range of robotic solutions for every industry and application such as materials handling, press brake tending, palletising and palletizing, machine tending and robot welding, plus more!

Industrial RobotS

Faster Cycle Times

- Improved acceleration / deceleration control for all robot positions allows faster cycle times.

- Increased axis speeds over previous generation.

Better Space Utilization

- Small footprint, slim-arm design widens work area, reducing overall space requirements.

- Hollow arm structure eliminates cable interference.

Less Downtime

- Highest wrist allowable moment provides reliable payload handling.

- Easy washdown cleaning in harsh or sanitary environments.

- Single-cable connection for fast setup and simple maintenance.

Collaborative Robots

Enhanced Worker Safety

- Power and Force Limiting (PFL) technology enables humans to safely work with robots.

- Smooth, yet durable, construction design eliminates pinch points.

- Through-arm utilities eliminate external cables and associated risks.

Optimized Production Rates

- Industrial-grade speeds and payloads for real-world applications (based on risk assessment).

- Easy programming and hand guiding facilitate quick changeover.

Fast System Integration

- Intuitive programming methods provide quick and easy learning curve.

Yaskawa Series

GP Series

Designed for fast-paced assembly, packaging and general handling processes, six-axis GP-series robots deliver optimal speed, accuracy and range of movement. The superior speed of this robot family is only matched by its nimble performance and simple, streamlined design. Most GP-series robots offer an IP67-rated wrist and IP54 body standard, with select models offering an XP (eXtra Protection) package that increases body protection ratings to IP65.

Human Collaborative HC Series

MOTOMAN HC Series robots are 6 axes human-collaborative robots (cobots) with a payload of 10-20 kg. Operator’s safety is assured by a Power and Force Limit technology that stops the robot in case of contact with an operator. HC Series robots can switch between safe collaborative speed and high speed, operate without additional protective measures like a safety fence, depending on the risk assessment.

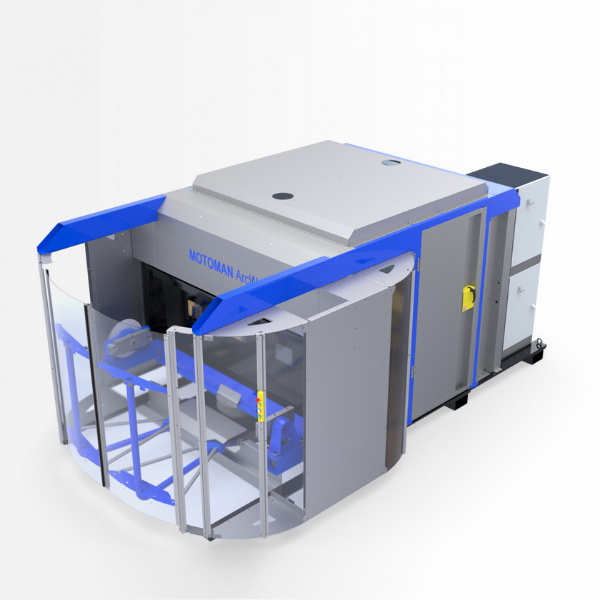

ArcWorld

Yaskawa Motoman’s ArcWorld® robotic welding systems are pre-engineered, pre-assembled and shipped ready to weld – delivering the most flexible and cost-effective options to integrate robotics into your welding processes. ArcWorlds can be configured with multiple robots, a heavy-duty positioner or servo-controlled external axes for coordinated motion.

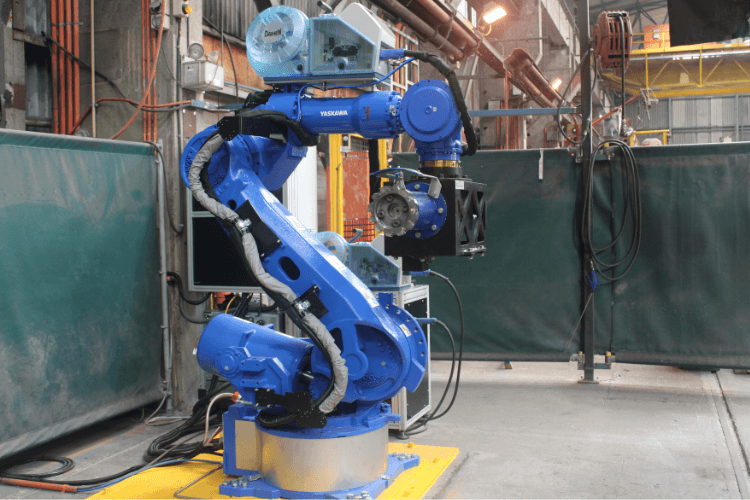

AR Series

The MOTOMAN AR Series Robots provide outstanding speed and accuracy for all kinds of demanding arc welding and thermal cutting applications, supporting all kind of welding and cutting methods and equipment. With a full range portfolio of working ranges between 700 and 3,124 mm reach, often in combination with our positioners, tracks and gantries, AR Series Robots can weld any kind or dimension of workpieces.

Robot Operator Training and Servicing

Yaskawa Online Training Academy

Due to ongoing requests from our customers we have collated a selection of YouTube videos that are an excellent training resource, we trust you will find these useful.

If you find other content or have suggestions of training videos you would like us to create and would be beneficial to the Online Training Academy we would love to hear from you. Please note, many of these videos are available on the public domain and copyright remains the property of the copyright holders. These are available free of charge.

Robotics Enquiry

Talk to the Robotic Automation Experts at Autoline to discuss your application and find out how robotic automation can help you increase your profitability, and reduce waste and rework through consistent quality, giving you a competitive edge in your industry.