Rapid Trial and Successful Commissioning Of Automated Steel Welding

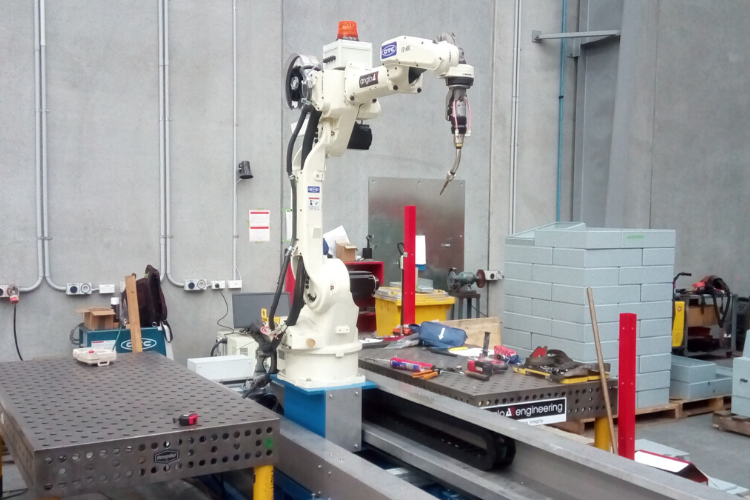

Customer: Anglo Engineering

Supplier: OTC Daihen by Autoline

The Challenge

A sudden increase in demand for their steel cabinets led Anglo Engineering to investigate ways to quickly automate highly repetitive welding operations.

The Solution

High-end technology was needed to match existing production equipment and meet contract engineering demand. A bottleneck at a highly-repetitive skilled MIG brazing operation was to be replaced by a robot. Trials were to be run on the live production line to prove quality and reliability.

The Outcome

Anglo Engineering directors found that Autoline were the only robotic system supplier in NZ able to set up and run the full on-line test trial within three weeks. Productivity increased substantially while boring repetitive tasks were reduced. Soon after, more Demmeler tables, a robot slider and off-line programming software were added.

See the link from the NZ Herald automation feature: https://www.nzherald.co.nz/business/news/article.cfm?c_id=3&objectid=12202604

Customer Feedback

Anglo Engineering Director Wayne Eccles has advised:

- Output of this steel cabinet product trebled compared to our previous manual welding.

- Neater/smaller welds have greatly reduced our clean-up times as these cabinets had 100% sanded joints.

- Welding wire and gas usage has decreased measurably.

- Output has been consistently high quality with reduced rework.

- 10% saving on bronze MIG brazing wire.

- 10% saving on shielding gas.

- We’re now pushing even more production welding tasks into the OTC robot welding cell for even greater productivity.