Robotic Assembly

Yaskawa Motoman offers manufacturers a wide range of robotic solutions for high-speed precision assembly automation. When using flexible robotics with 2D and 3D vision systems and various parts feeding methods, manufacturers can be confident in their capabilities to produce today’s product, with flexibility to change and expand in the future.

What is Robotic Assembly?

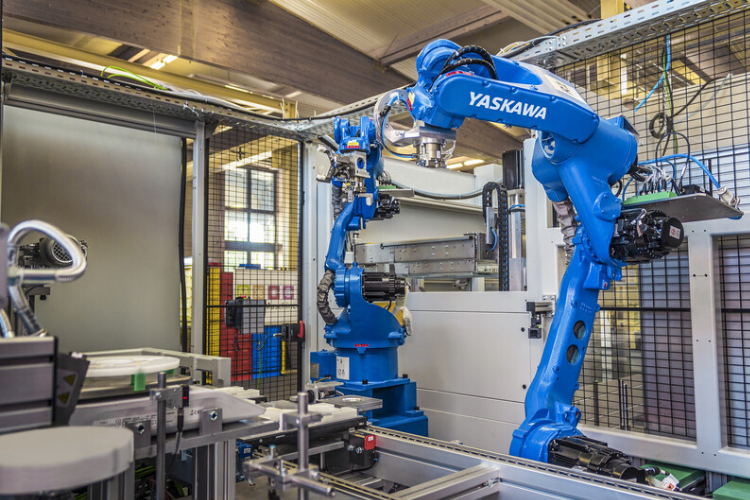

Industrial robots can be used to automate the tasks involved with putting together a product, such as automotive assemblies, furniture, machinery, or electronics components. This can often be done using a 4- to 6-axis robot that is capable of human-like levels of dexterity. Specialized tooling or grippers attached to end of the arm work with the axes of the robot to manipulate and attach parts. Robot vision components are often integrated into an assembly automation system to identify and sort parts, ensure proper placement and inspect the finished product.

Types of Automated Assembly Tasks

- Part Identification

- Part Sortation

- Flexible Feeding

- Bin Picking

- Tool Changing

- Force Sensing

- Part Fastening or Joining

- Visual Inspection

Using robotics for assembly automation results in:

- more manufacturing flexibility to produce a wider range products with faster time-to-market

- faster changeover times, increased system up time and asset utilization

- increased product quality with predictable results with error checking and in-line testing

- increased productivity with shorter payback

- optimized workflow designed around your value-added processes, not your fixed automation

- elimination of expensive and dedicated hard automation