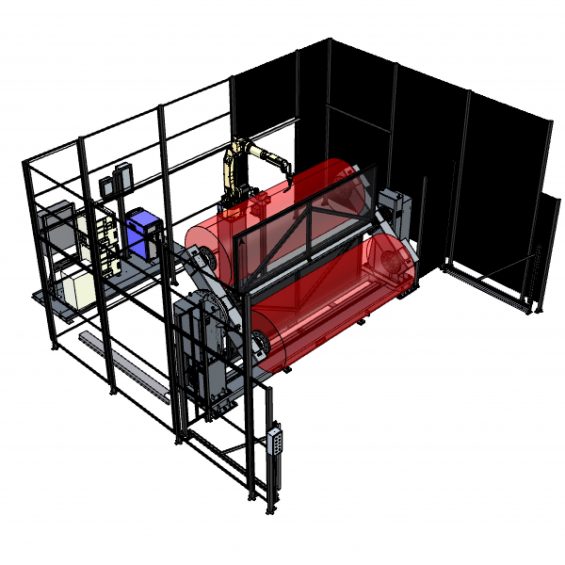

TRI-ARC 1000

Description

The OTC TRI-ARC 1000 is a three-axis, servo-controlled positioning cell offering dual head and tailstock positioning stations and a primary rotational axis to present each station to the robot. The heavy-duty design accommodates large components up to 3500mm in length and requires less floor space use while allowing single load and unload points for minimal operator movement during operation.

Arc Welding Robot

- Offers a wide working range with an independently articulated arm

- Seamless digital connection with all OTC DAIHEN brand welding power supplies

- Improved vibration restraining control provides smooth robot movement

- Built-in mechanical shock sensor

- Single source technology – all components are manufactured by OTC DAIHEN

- Highly versatile design supports most welding applications

Robot Controller

- Windows XP based open architecture

- Large memory capacity and 40 Input / 40 Output control signals

- Advanced PLC functions allow for ladder diagram editing directly through the teach pendant

- Network capabilities – connects to Ethernet, DeviceNet, and PROFIBUS connections (may require additional hardware)

- Improved specification for severe condition such as high-humidity and high-temperature

Teach Pendant

- Icon displays assist in quick & easy teaching

- 640×480 VGA color screen

- 3 position enable switch provides increased safety

- Multi-screen function allows user to view up to 4 screens simultaneously

- On-screen help function with complete instruction manuals

- Standard touch screen display with jog dial operation