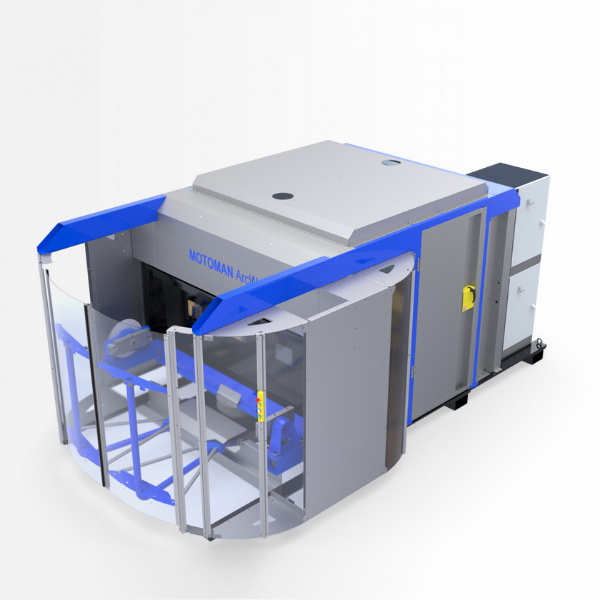

ArcWorld CS

Description

All in one place, easy to install, easy to operate, and easy to move around the factory floor if the production needs changes. Based on a platform, ArcWorld robotic welding stations are simply full of user-friendly features designed for the best possible performance in the smallest possible space. ArcWorld CS has a separate working area for the robot and operator respectively.

Key Benefits:

• Easy to operate.

• Short delivery times.

• Small footprint, but generous space for the robot.

• Easy to install, and to relocate on site.

• Material can be loaded with an overhead crane.

• Practical and bright environment for the operator.

• Prepared for offline programming.

User-friendly Design:

In ArcWorld CS the operator and robot have their own separate working area. This provides the operator with a practical and bright workplace with curved sliding doors and the required materials close at hand.

Scope of Delivery:

• Platform, metal walls, curved sliding flexi doors.

• Fume hood with outlets for ventilation and exhaust.

• MOTOMAN welding robot, or robots.

• Positioner or a fixed table.

• Start panel.

• CE-marking.

Easy to Connect:

Simply plug in the main power to the power distribution box located on the back of the ArcWorld CS. Internal connection to the robot controller and interior lightning is already in place. In addition to the outlet for the welding power source, the power distribution box also has extra sockets for 230VAC and 400VAC that can be used for other equipment. Sockets for connecting the pressurised air are located nearby.

Platform Design:

Robot, positioner, controller, and power supply are all mounted on a common platform. This makes it easy to move the ArcWorld and start up again if needed.

Twin Robot Option:

It is possible to have two welding robots without increasing the floor space