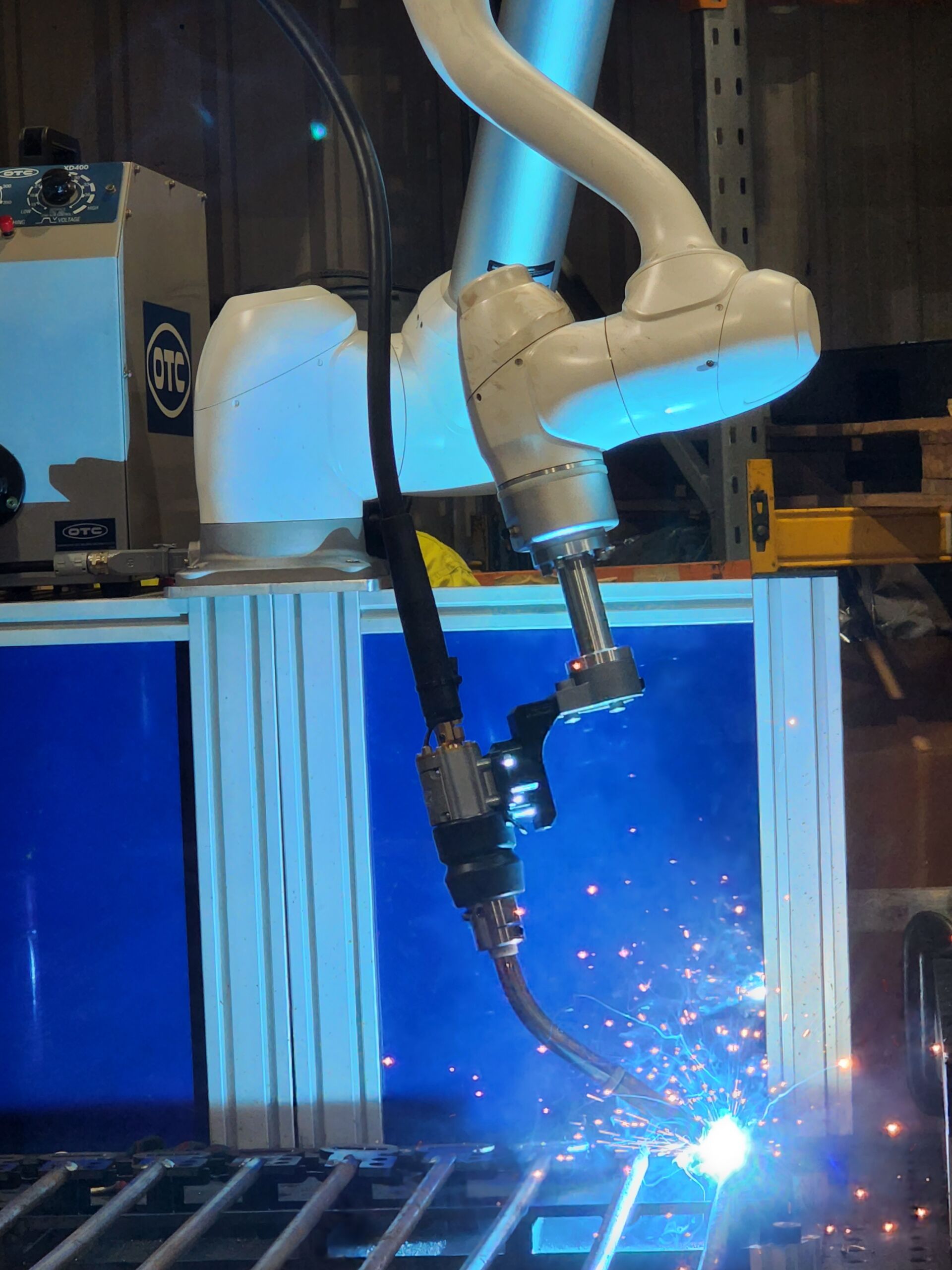

Manufacturing companies around the world are experiencing a shortage of skilled labourers, especially welders. As the number of qualified welders declines, companies struggle to maintain productivity and quality output. But one of New Zealand’s leading providers of robotic and productivity solutions, Autoline, has a solution to this problem: robotic welders that can be hired for short or long-term programs and come as a complete ready-to-weld package.

“Autoline’s fleet of high-quality robotic welders are equipped with advanced features that ensure maximum efficiency and reliability in welding tasks. All equipment is fully serviced before being hired out to customers. The robots are available for hire with flexible terms ranging from one month to three years,” says Matthew Fisher, Autoline’s managing director.

Autoline offers complete technical support to ensure that the robotic welders are operating at peak efficiency.

“We are a single-source solution, meaning that we handle everything from delivery to installation and ongoing support. Our comprehensive package includes everything needed to get started, so manufacturers can quickly and easily integrate the robots into their production processes,” says Fisher.

With robotic welders, manufacturers can maintain consistent quality output, reduce waste and consumables, and ensure employee health and safety.

“The use of robots improves productivity and empowers existing employees to work more efficiently and effectively. By outsourcing repetitive tasks to robots, employees can focus on more complex projects, increasing their job satisfaction and overall well-being.”

In addition to solving the skilled labour shortage, Autoline’s robotic welding solutions offer numerous benefits to manufacturing companies. First, robotic welders can work non-stop, resulting in higher production volumes and faster turnaround times. Robotic welding also reduces the risk of human error and inconsistency, ensuring that products meet the highest quality standards. Also, robotic welding reduces waste and consumables, ultimately saving manufacturing companies money in the long run.

“At Autoline, we have over 35 years of experience in the automation industry, and we fully understand process and production improvement requirements. Our team of experts will work with your company to develop a robotic welding solution that meets your specific needs, allowing you to focus on growing your business while we take care of the welding tasks.

We are committed to providing our customers with high-quality equipment that delivers reliable, long-lasting performance.”

Fisher says that hiring a robotic welder is a smart investment for any manufacturing company looking to stay competitive in today’s market.

“With Autoline’s flexible hire programmes, companies can gain access to advanced technology without the need for large capital investments. The complete ready-to-weld package, top-quality equipment, and complete technical support means hiring a robotic welder has never been easier. Get in touch with us and learn more about our many robotic welding solutions.”