When deciding between industrial and collaborative robot palletisers and finding the right robotic automation system for your production line, there are four main characteristics to consider.

1. Payload

Number one is what is your required payload? Collaborative robots have lower payloads than industrial robots do.

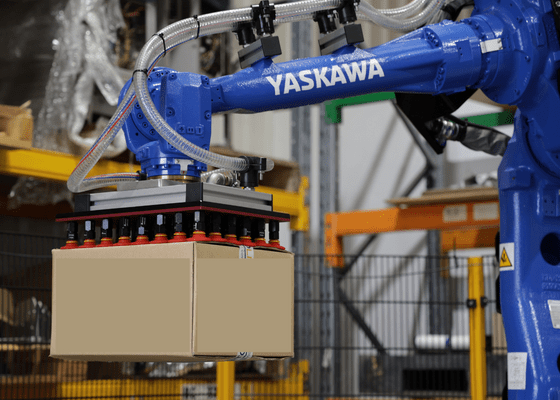

Doosan has a heavy range of collaborative robots (cobots) which are called H-Series, these are the most powerful cobot in the market, with an outstanding payload of 25kgs. Yaskawa Motoman has a wide range of industrial robots with maximum payloads and reaches, therefore payload is not often a problem for industrial robot palletising. In summary, if you are trying to lift a payload that is greater than 25kgs, you would need to consider looking at an industrial robot palletiser solution rather than a collaborative one.

2. Reach

The next consideration is reach, how high do you need to stack your boxes on the pallet? The H Series models from Doosan have a reach of 1500mm and 1700mm which is outstanding flexibility for the powerful payload of 20kg and 25kg! Once your required reach is above the maximum reach for the collaborative robot arm, it may be difficult for a collaborative robot to meet your needs. In this case, industrial robots have larger reaches and would likely suit the application better.

3. Work Efficiency

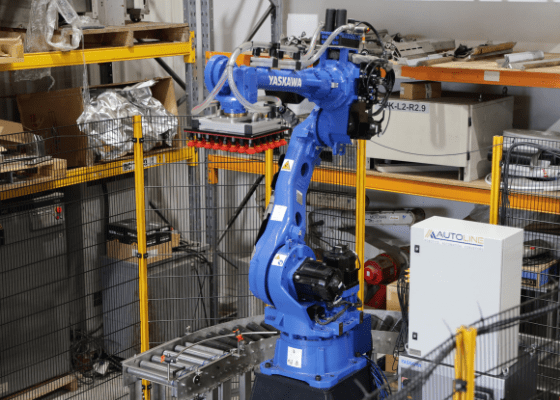

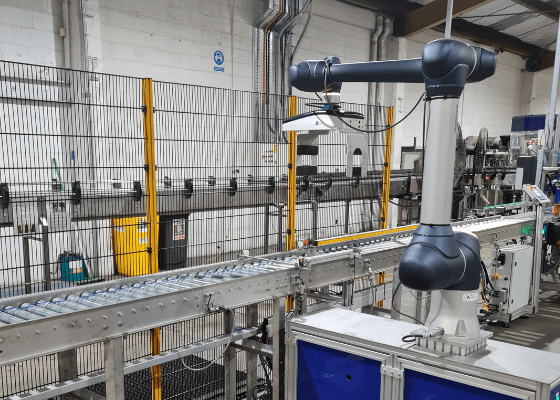

The third consideration is what space do you have available on your production floor? A collaborative robot palletiser has a smaller footprint than an industrial robot palletiser system and takes up less physical space. Cobot palletisers also don’t require any guarding due to the industry’s best collision sensitivity powered by 6 torque force sensors, this allows humans to work alongside the collaborative robot safely. Whereas Industrial Robots require full safety guarding and sensing around the perimeter of the footprint to protect humans. It depends on the layout of your production line and floor space you have to determine whether an industrial robot or a collaborative robot would suit your palletising application best.

4. Speed

Industrial robots and collaborative robots have similar cycle times, the reason that industrial robots can handle such high volumes is due to their higher payload capacity. Depending on the weight you are trying to lift, industrial robots can lift a whole layer of boxes or bags in a cycle whereas typically a collaborative robot only lifts one box at a time.