History of Robotics In New Zealand – We Are Helping Kiwis Keep Manufacturing In New Zealand.

Autoline has been trusted by Kiwis for over 35 years in robotics and automation. Today, it has never been more important to help New Zealand increase our manufacturing industry and help clients through the often-daunting task of automation.

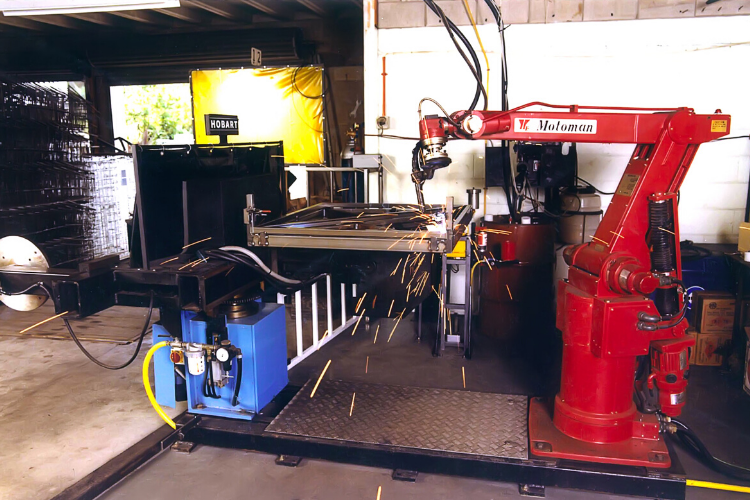

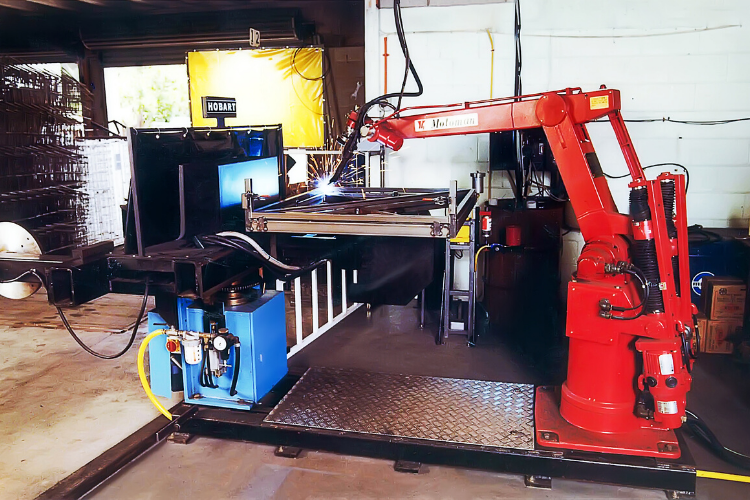

Over the past few weeks we have been going through our photo archives of the first few robotic welding cells installed by Carbines Engineering, some of which were commissioned over 35 years ago!

We have decided to share these images with you, to show how we have been helping kiwis keep manufacturing in New Zealand all these years!

Company: Anderton Holdings Limited

Installed: Year 1984

Application: Welding Shopping Trolley Components

Model Robot: Motoman L-10WA

Motoman-L10WA History

The Worlds First 6 Axis Robot

Motoman-L10WA:

- Introduced in 1983

- Six axes

- Maximum workload 5kg

- Weight 280kg

Control System RG:

- Introduced in the 1980s

- Controls up to 6 axes

- Programming capacity 1000pos (600 instructions)

- 99 Robot jobs in magnetic memory (external memory on tapes)

- 22 Input signals and 21 output signals

- 127 Welding parameters

- Liner and circular interpolation possible

- Dimensions 1600x650x700mm

- Weight 350kg

Improvements To Robot and Controller

The work area in the new Motoman L10W was increased by 80% and the robot wrist is more narrow. The robot was made of a light aluminium alloy which helped reduce the size of its motors.

The model L10WA, with its extra wrist axis called A, was the world’s first six axes robot. The control system RG could handle either this robot model, or the ordinary L10W and an external axis. However, the L10W-models were almost exclusively used with the next generation controller RX.

The later versions of RG control system enabled circular and linear interpolation, three dimensional shifting of a robot job and pendular motion. It was even possible to control it from an external computer, but that was not put to much practical use.