Company: Franklin Machinery Ltd

Installed: February 1985

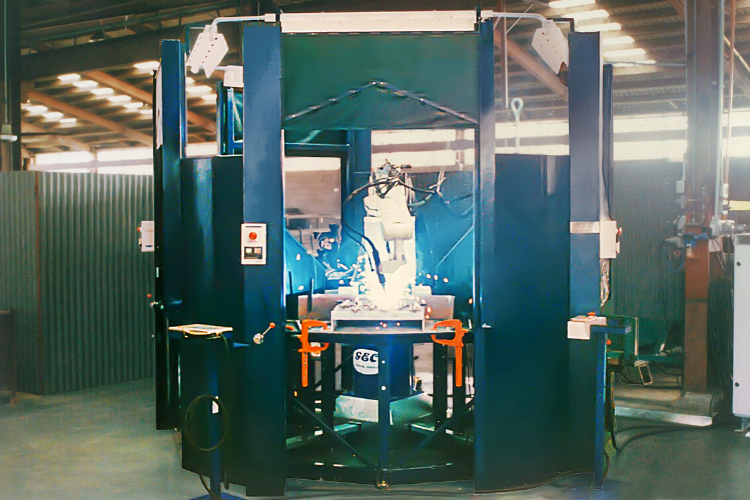

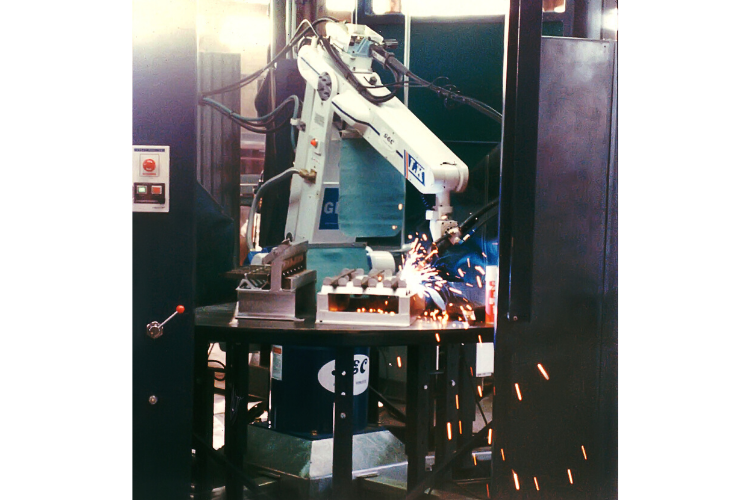

Application: Farm Gate Hardware

Equipment: OTC LK 6 axis robot with OTC transistor pulsed MAG TRM-350 welder, 4 Automatic Guard System’s

OTC Daihen-LK History:

- Introduced in 1985

- Six axes

- Capable of performing TIG/MIG welding operations without causing interference to their controllers

The OTC LK robot was a six-axis (five axes plus gyro axis) robot. The robot and controller was capable of performing TIG and MIG welding operations where the robot and controller were fully isolated from the harmful effects of the high-frequency impulses generated during MIG/TIG welding.

In addition to the LK there are the LA and SA robots, all three of which were available for MIG welding. All come with a magnetic bubble memory controller enabling large welding programs to be stored (99 programs!)

A feature of the OTC controllers was the use of a teach pendant which gave simple commands in language understandable by welding engineers. Optional welding equipment included 350A air-cooled or 500A water-cooled torches and a welding torch shock sensor. When the welding torch shock sensor was fitted, the robot would automatically shut down if any external forces were sensed. This protected the torch, tooling and work piece from any accidental damage.

OTC Daihen has a long and eventful history in New Zealand, introduced by Carbines Engineering 35 years ago, New Zealand’s first and original robotic company.

OTC Daihen was established in 1919 as a manufacturer of transformers. It began manufacturing welding equipment in 1934. Since then, the company has grown steadily to meet both Japanese and world markets. It’s product range covers arc welding machines, arc welding robots, plasma cutting and welding machines, carbon dioxide laser equipment and electron beam welding equipment.