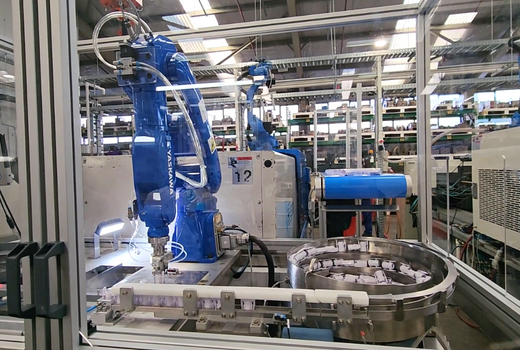

Vibratory bowl feeders are key components in industrial automation. They are widely used in industries like automotive and electronics. Additionally, these components play a crucial role in enhancing precision and efficiency in part feeding for assembly lines.

Essentially, vibratory bowl feeders consist of a vibratory drive unit and a custom-designed bowl. The drive unit generates controlled vibrations, moving parts within the bowl along a spiral or circular path. The unique geometry of the bowl ensures that the parts align themselves consistently, facilitating efficient sorting and orientation.

Applications of Vibratory Feeder Bowls

- Automotive Manufacturing – feeding and aligning small components like screws, bolts, and fasteners.

- Electronics Assembly – handles delicate components such as chips, resistors, and connectors with precision.

- Medical Device Production – assembling complex medical devices, ensuring accurate alignment of small components.

- Consumer Goods – from toys to electronics, vibratory bowl feeders play an important role in the assembly and packaging of consumer goods.

Benefits of Vibratory Feeder Bowls

- Precision and Consistency – Controlled vibrations result in precise part alignment, reducing errors in downstream processes.

- Versatility – Can handle a diverse range of parts, making them adaptable to various industries and production needs.

- Customisation – Manufacturers can tailor vibratory bowl feeders to specific part sizes and shapes, enhancing integration into existing production lines.

- Increased Efficiency – Automation of the feeding process reduces manual labour, improving overall production efficiency.

- Cost-Effectiveness – While there is an initial investment, the long-term savings in labour costs and increased productivity make vibratory bowl feeders cost-effective.

- Low Maintenance – Few moving parts and robust construction contribute to low maintenance requirements, ensuring continuous operation.

Vibratory bowl feeders continue to evolve as technology advances. Integration with smart manufacturing systems, improved control mechanisms, and enhanced sensor technologies are likely to further optimise their performance. Thus, making them even more integral to the future of industrial automation.

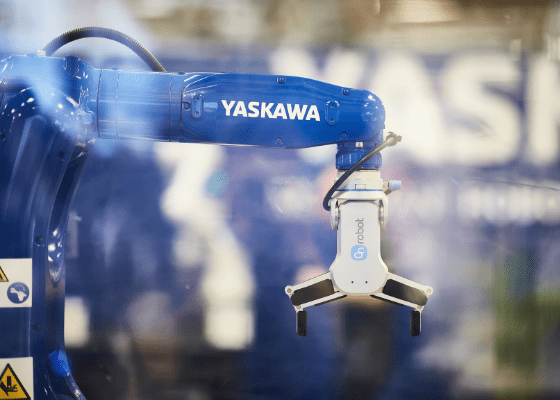

Ready to elevate your manufacturing processes? Autoline, a leader in robotics and automation, is here to help. Reach out to Autoline today and take the next step towards enhancing your precision and efficiency. We can work together to shape the future of manufacturing excellence.