Autoline is a leading New Zealand Conveyor Systems Manufacturer and Solutions Provider. We specialise in designing and manufacturing customised systems to meet the diverse needs of manufacturing companies across various industries. Our solutions are built with precision and durability, streamlining material handling processes and optimising workflow.

Additionally, we have the expertise to integrate new innovative robotic equipment into existing systems. By combining our systems with robotic technology, we enhance the productivity and capability of manufacturing processes. However, we also provide standalone conveyor solutions for those who don’t require robotic equipment.

Autoline Conveyor Solutions

Key Benefits of Autoline’s Conveying Solutions

Autoline’s conveying solutions offer a multitude of key benefits for manufacturing companies.

One of the primary advantages is enhanced efficiency. Our meticulously designed conveyor systems streamline material handling processes, reducing the need for manual labour and improving overall operational efficiency.

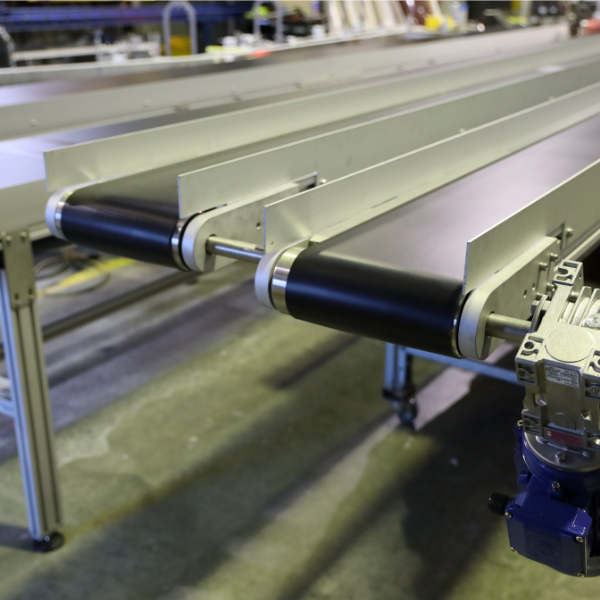

We understand that every business is unique, which is why our solutions provide a high level of customisation. From belt conveyors constructed with our SlotPro T-slot aluminium extrusion system to roller, modular, and gravity conveyors, our range of options allows for tailored solutions that meet specific requirements.

Moreover, Autoline’s conveyors are built to last, ensuring durability and reliability for long-term performance and minimal downtime.

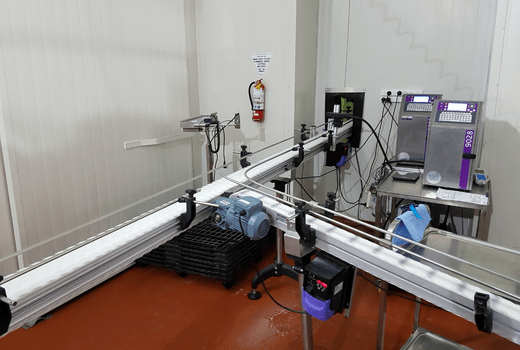

The flexibility of our systems allows for easy integration into existing production lines or adaptation to accommodate changes in manufacturing processes.

We prioritise safety by incorporating features such as sensors, emergency stops, and protective guards, creating a secure working environment for operators.

Autoline’s conveying solutions optimise workflow, maximise productivity, offer customisation options, ensure durability and reliability, provide flexibility, and prioritise safety.

Specialty Conveying Solutions

At Autoline, we pride ourselves on our ability to design and build specialty conveyors that are tailored to meet the unique requirements of your application and industry.

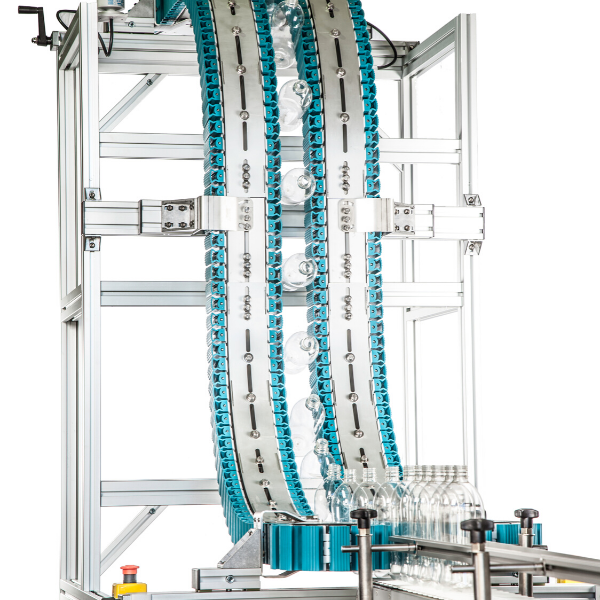

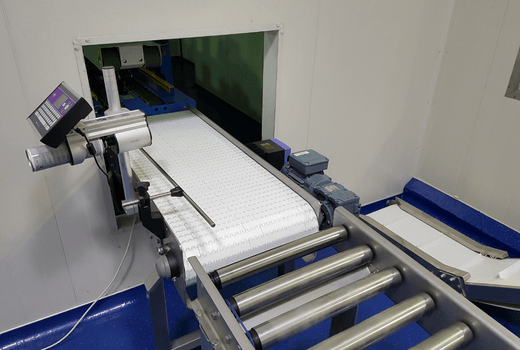

Our expertise extends beyond standard systems, allowing us to create custom specialty systems that address specific needs. Whether you require an elevator or lowerator for vertical movement, 90-degree and spiral conveyors for directional changes, accumulation conveyors for buffering or sorting, gripper conveyors for handling irregular-shaped items, slat chain conveyors for robust and heavy-duty applications, or stainless steel conveyors for food-grade environments, we have the capability to deliver.

Our specialty conveyors are meticulously designed and built to ensure optimal performance, reliability, and durability, providing you with a solution that perfectly suits your industry and application requirements.

Conveyor Componentry

Discover Autoline’s conveyor componentry range, provided to elevate the performance and adaptability of your systems. Explore our diverse selection of high-quality accessories, such as casters, side guides, drive drums and more.

If you have unique requirements, our dedicated team is ready to assist you in finding the perfect solution. Trust Autoline to deliver the components you need to optimise your conveyor systems and achieve unparalleled efficiency.

Why Automate With Conveyors?

Increased Efficiency and Productivity

Automation with conveyors eliminates manual tasks, enabling faster and more accurate handling of materials, reducing bottlenecks, and improving overall efficiency. Reduced production time leads to improved productivity levels.

Consistency and Precision

Automated systems provide precise control over the movement of items, ensuring consistent positioning, orientation, and delivery. Quality is improved by reducing the risk of errors, damages and contamination during transportation.

Cost Savings

By automating repetitive tasks, businesses can reallocate labour resources to more value-added activities, optimising workforce utilisation and reducing labour costs.

Traceability and Data Collection

Automated conveyors can integrate with tracking systems, enabling real-time monitoring, data collection, and traceability of products throughout the production process.

Improved Ergonomics and Safety

By minimising the need for manual lifting and handling, automated conveyors contribute to a safer and more ergonomic work environment. These systems can also incorporate safety features such as emergency stop buttons and sensors to ensure operators are protected.

Scalability

As companies grow, systems can be easily expanded and preconfigured to accommodate increased production volumes or changes in manufacturing processes.

Enquiry

Talk to Autoline’s Automation Experts to boost your profitability and gain a competitive edge. The more information you can provide, the more accurate our response and quote will be! Unlock the power of automation for your business today!