treamline production for the removal of moulded parts with versatile robots and intuitive tools.

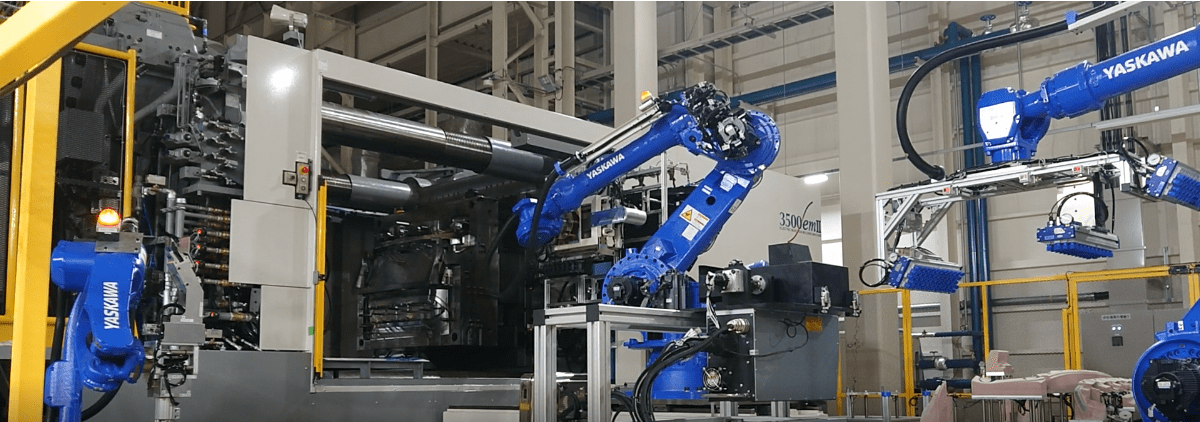

Market trends and labour force realities are prompting manufacturers to add automation to their injection moulding operations. Alleviating production bottlenecks and providing operational flexibility, contoured six-axis robots and innovative electrical interfaces are easily accommodating the efficient removal of moulded parts from injection moulding machines (IMMs).

Join Product Manager, Chris Caldwell, to discover how highly reliable, cost-effective robots and their peripherals can add the capability to your shop floor.

Gain Insights On:

- How robots can improve your production processes

- What type of robots work best for injection moulding

- Why articulated robot arms are beneficial vs. gantry-style robots

- What tools can streamline the robotic removal of parts from IMMs

- Yaskawa’s SPI-67 electrical interface

- Where else can robots help on your shop floor

- What is the best way to monitor system uptime

Who should attend?

- Plastics industry professionals and integrators

- Injection moulding manufacturers and suppliers

Webinar Details:

Date: Thursday 27th January 2022

Time: 8.00am NZDT