Discover The Ideal Palletising Solution For Your Operation!

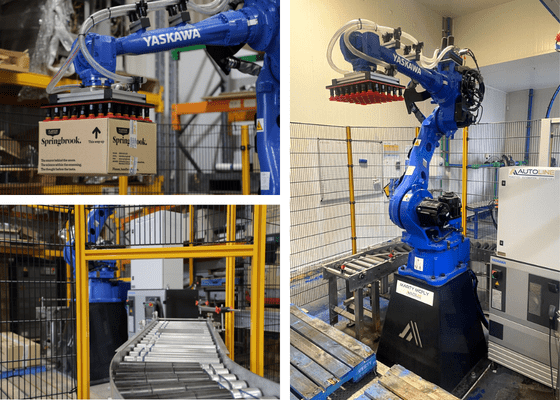

One of the fastest growing applications, extremely fast and repeatable, robotic palletising is providing improved safety and increased productivity across the industrial landscape. Unlike manual palletising which often involves repetitive lift and twist motion for heavy packages, robotic palletising saves workers from having to perform this potentially harmful task and allows them to complete other value-added activities. Along with this, robotic palletising optimises floor space utilisation, saving valuable space compared to fixed machinery.

Join Yaskawa expert, Chris Caldwell, as he takes a deep dive into the wide variety of solutions available for this application. From collaborative and industrial robots to numerous peripheral technologies and integration partners, much will be discussed.

Topic Highlights:

- Brief market overview

- Manual vs. fixed vs. robotic palletizing

- Types of robotic palletizing (collaborative, industrial, mixed case)

- Popular robot options by type

- Palletizing software and solutions

- Palletizing workcell design considerations

Who Should Attend:

- Manufacturing managers from Food & Beverage, Consumer Goods, Wood Products, Paper Products, Plastic and Chemical Industries, Electronic Component Manufacturing, Automotive Parts & Accessories, Logistics & Warehousing, and Construction Products (specifically heavy bagged items).

- Decision makers looking for a simple and cost-effective way to implement versatile robots with flexible tooling onto their production floor.

Webinar Details: Thursday 8th September 2022 | 6:00 AM NZST