Robotics Welding Simplified: Autoa’s AI Path Planning Software Sets New Standards in New Zealand

In the ever-evolving world of engineering, precision and productivity are paramount. Autoa, a brand of Autoline, is leading the charge with its state-of-the-art Welding Cells equipped with industry-defining AI path planning software. These cutting-edge systems are revolutionising the welding landscape in New Zealand, specifically designed for high mix low volume (HMLV) welding production. This software brings significant enhancements in productivity, speed, and flexibility, catering to sectors like stainless-steel fabrication and aluminium boat building.

Introducing a New Era of Precision and Efficiency: Autoa’s AI Path Planning Software

Autoa’s AI path planning software represents a paradigm shift in the welding industry. Developed by Autoline, this proprietary software combines the power of artificial intelligence and machine learning to redefine welding tasks, introducing a new era of efficiency and precision. By analysing a multitude of variables, the software swiftly determines the most effective welding path for each unique task, with a focus on achieving consistent high-quality welds while maximising productivity.

Redefining Industry Standards: Autoa’s Software vs. Cobot Welders

When comparing Autoa’s AI software to cobot welders, the distinction becomes clear. While cobot welders are renowned for their user-friendly nature and their potential to address skills shortages, Autoa’s software surpasses them in terms of efficiency and speed. The AI software significantly reduces programming time, a crucial factor in HMLV production, allowing manufacturers to adapt seamlessly to design changes and shifts in production volumes. The promise of easy programming by cobot welders’ pales in comparison to the transformative capabilities and agility offered by Autoa’s revolutionary software.

Enhanced Productivity with Autoa Welding Cells

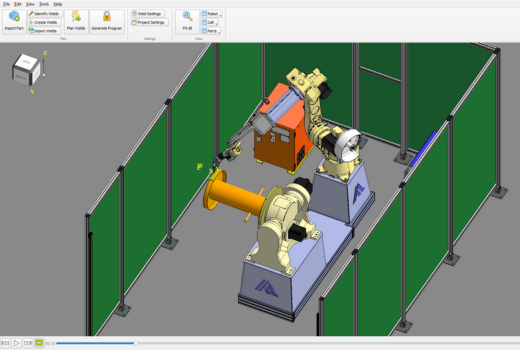

Autoa Welding Cells, manufactured by Autoline, are known for their robustness and high performance. When combined with the Autoa AI path planning software, these welding cells achieve even greater effectiveness, enabling manufacturers to transition between different products without disrupting the production flow. The powerful combination of Autoa Welding Cells and the revolutionary software not only enhances productivity but also makes complex tasks achievable that were previously challenging with traditional welding methods.

In conclusion

Autoa’s unique AI path planning software is reshaping the welding industry in New Zealand. Manufactured by Autoline, Autoa Welding Cells equipped with this revolutionary software have proven to be efficient, viable, and cost-effective for HMLV production, making them the preferred choice for fabricators nationwide.

With Autoline’s strong commitment to local innovation, Autoa’s software developed on home soil is ushering in a new era of welding productivity and efficiency, shaping the future of fabrication in the country. The Welding Cells equipped with this AI software not only exemplify the technological advancements in the welding industry but also empower fabricators with enhanced productivity, speed, and flexibility, positioning them at the forefront of the engineering industry.

Three Simple Steps To Robot Welding Success

We are excited to invite you to a live-streamed presentation that will showcase the game-changing potential of high-mix low-volume robot welding.

This is a must-see event for both existing robot users and those exploring the possibilities of robot welding!

Date: Friday 23rd February, 2024

Time: NZT 3:00 PM | AET 1:00 PM | ACT 12:30 PM | AWST 10:00 AM