Auto-CoPal

Description

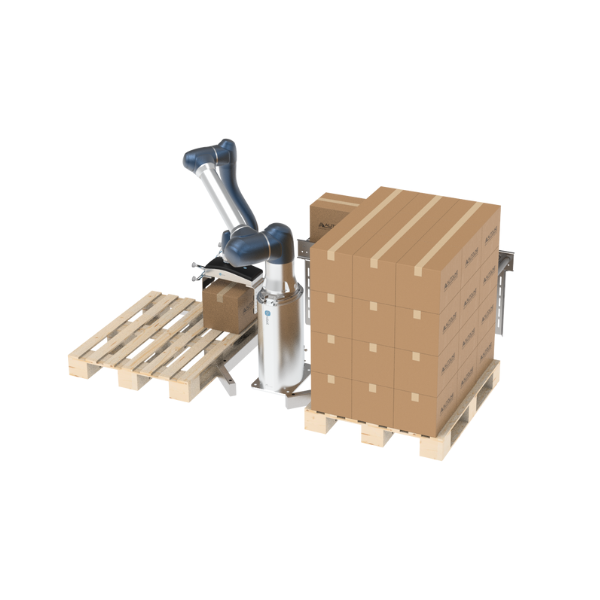

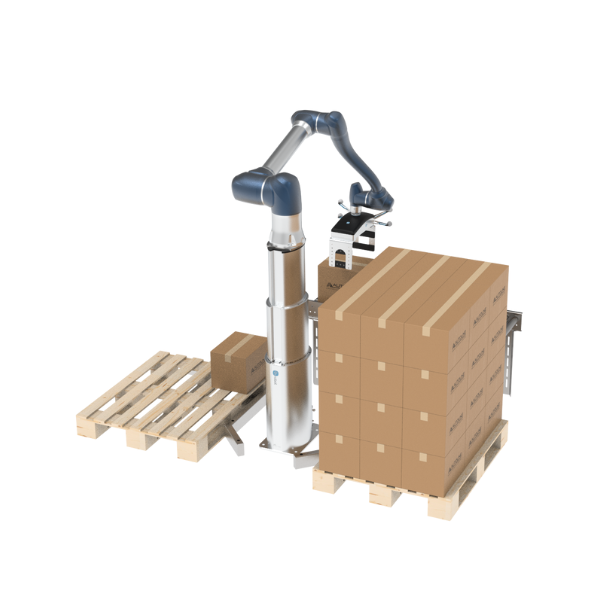

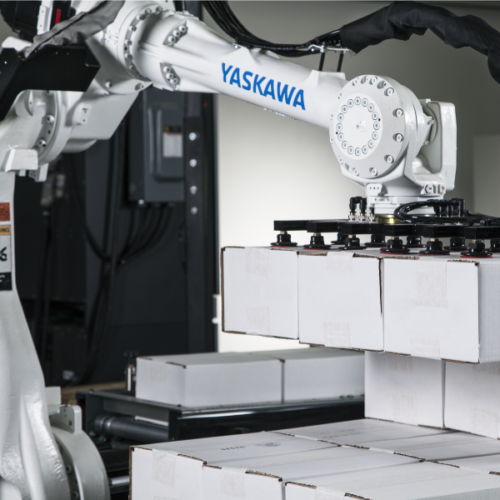

Introducing the Auto-CoPal, a collaborative robot palletiser system designed to automate the palletising process and revolutionize manufacturing facilities. With its ability to handle various types of products and pallet configurations, the Auto-CoPal palletiser is a versatile solution that can be adapted to different manufacturing processes, helping increase productivity, reduce costs, and improve safety.

This cobot palletiser is a reliable and efficient solution that picks cartons or boxes from a conveyor belt and places them on a pallet in the required configuration, eliminating the need for manual intervention and reducing the risk of errors. With its advanced technology and user-friendly interface, the Auto-CoPal is the perfect solution for automating your palletising processes.

The Auto-CoPal robotic palletiser is easy to integrate into your facility, requiring minimal setup time and no machine safety guarding. Its compact design ensures that it can fit into even the smallest floor space constraints. Plus, with its powerful torque sensors on each joint, the Auto-CoPal is highly sensitive to collision detection, ensuring operator protection.

With the Auto-CoPal, you can enjoy a faster, more efficient robot palletising process that produces high-quality results every time. It is a reliable and efficient solution for companies looking to streamline their palletising process and increase productivity. Don’t wait, automate your manufacturing facility today with the collaborative robotic palletising system – AutoCoPal.