New Zealand’s Manufacturing Experts.

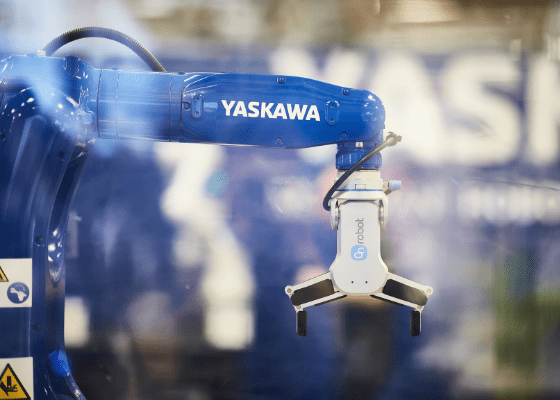

Trusted in Robotics and Productivity Solutions.

Welcome to Autoline, New Zealand’s trusted manufacturing experts in robotics and productivity. We offer advanced robotic welding and tailored automation systems, designed to enhance efficiency, safety, and production quality for your business. Our cutting-edge solutions minimize waste and rework, leading to increased profitability and a competitive edge in your industry.

Discover our comprehensive range of robotic welding and automation solutions, designed to meet the unique demands of your business. Contact our team of experts today and unlock your company’s full potential with Autoline – your trusted partner in robotics and productivity.

Representing World Leading Robot Brands

Latest Industry Insights

Keep up to date with the latest Robotic and Automation Technology.

Subscribe To Our Newsletter