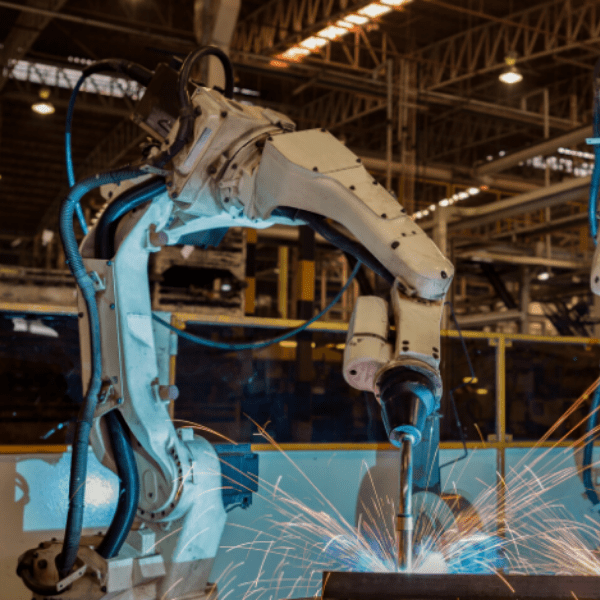

Robotic Welding

Description

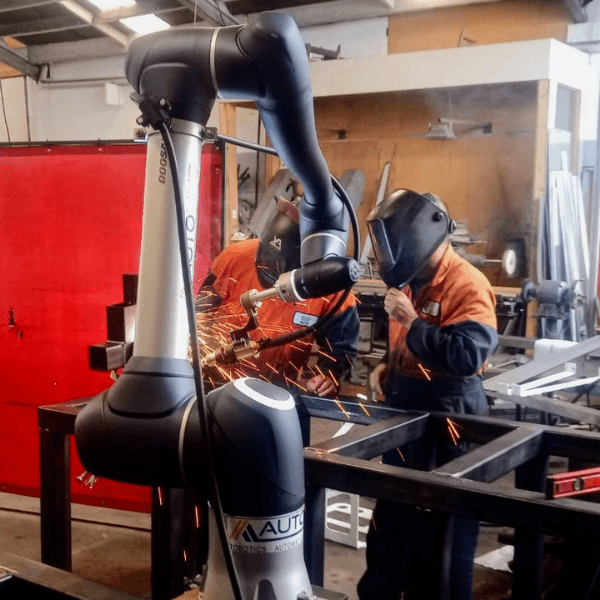

Autoline is the expert in Robotic Welding systems and solutions, bringing world-leading robot brands and the latest technology to New Zealand.

From industrial robot welding to collaborative robot welding systems, Autoline can offer a solution to meet your welding requirements. Whether it be heavy duty welding or welding small parts, MIG or Aluminium welding, our systems can be customised to suit.

Autoline is proud to represent the following world-leading brands in New Zealand which provide multiple options and systems for robotic welding.

Click on the brand names below to read more and view the products available:

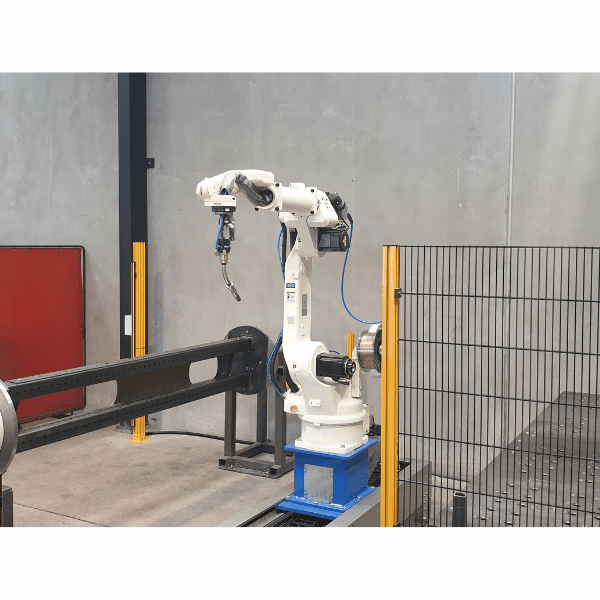

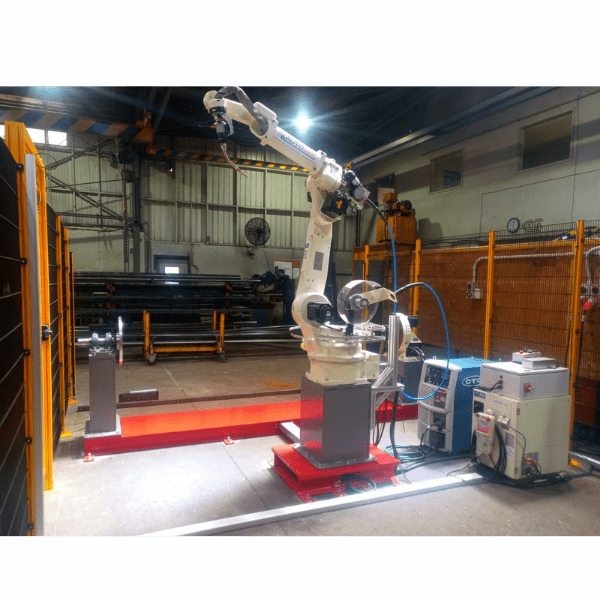

OTC Daihen – A single-source solution for welding, providing all the robotic welding equipment and technology you need for a reliable, repeatable and clean welding system.

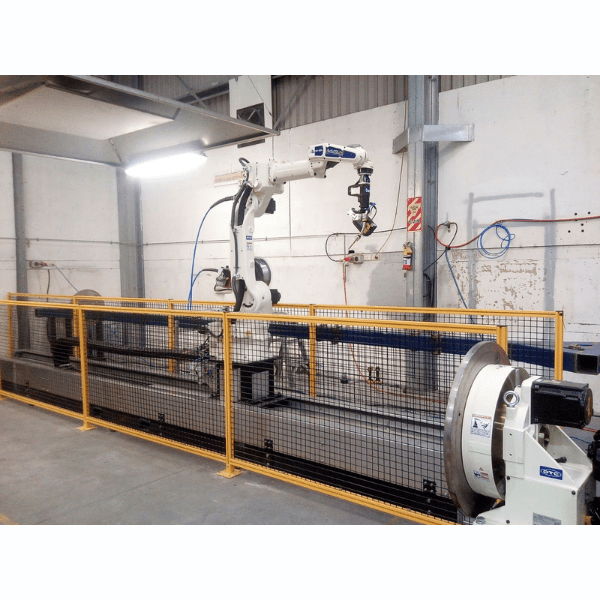

Yaskawa Motoman – Features special welding robots that reduce weld distortion, shorter the cycle and programming time, increase efficiency and a very flexible welding system.

Doosan Robotics – A range of collaborative robots which can be applied to cobot welding.

View our recent Robot Welding case studies here.

What are the benefits of Robotic Welding by Autoline?

A robot does not tire or take sick days. You can count on consistent and regular output from one of our welding robot systems. In a typical welding robot application, one robot will do the equivalent output of 3-4 full-time employees. A robot’s extreme accuracy and repeatability also lead to quicker welding times. This decreases labour costs at the same time as increases productivity. After labour one of the largest costs in any welding department are consumables. Robots know exactly when to stop welding and when to move on, without overusing these materials. Typically a welding robot will save approximately 15% on welding gas and wire consumables.

Perfection is not achievable with an operator welding repeated parts, it will always result in some type of inconsistency due to human error. With robotic welding, you will greatly reduce the need for rework as being programmed correctly, there is absolute certainty the welds will be the exact same high-quality weld every time.

With a robotic welder at work, the robot operator is more separated from the welding fumes and arc. This results in less exposure to hazardous risks for your employees.

Key Benefits of Robotic Welding:

- Increase in Productivity and Output

- Decreased Waste and Scrap

- Improved and Consistent Weld Quality

- Reduced Dependence on Manual Labour

- Labour and Consumable Savings

- Improved Health and Safety

Talk to the Robotic Welding Experts at Autoline to discuss your current welding processes and find out how a robot welding system can help you increase your profitability, giving you a competitive edge in your industry.

[email protected] | 0800 37 55 66