Autoline Cobot Welder Ex Demo

Description

Automate repetitive welding tasks with the Auto-CoWeld, a safe and easy to program collaborative robot platform. A collaborative robot welder is a low-cost and effective way to get started with welding automation. It is a flexible automation solution that allows manufacturers to increase their capability quickly and easily.

The Auto-CoWeld ensures maximum flexibility, easy programming, and consistent high-quality welds, for a rapid return on your investment. For engineers that have low-volume, high-mix manufacturing, the Auto-CoWeld is ideal. Being quick and easy to teach via the Doosan teach pendant makes automated welding of smaller batches economical. Also, you have the ability to adjust weld parameters and speed during the welding process using the teach pendant.

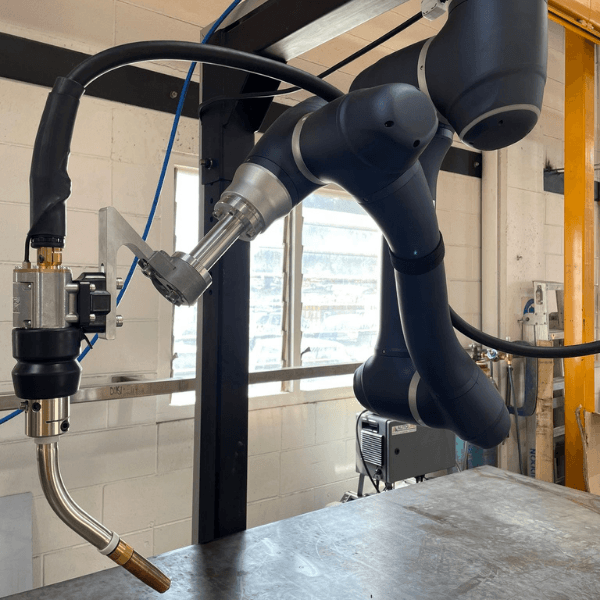

Our Auto-CoWeld is a configuration of reliable and proven technology with a Doosan Collaborative Robot and OTC Daihen Welding Hardware. This innovation is a combination of world-leading cobot, and welding technology manufacturers bought together by Autoline.

Collaborative welding offers benefits to manufacturers such as:

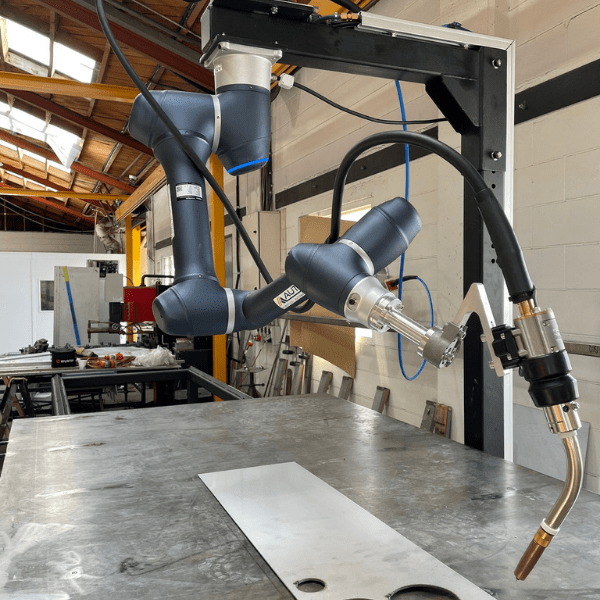

Quick and easy to teach – The Auto-CoWeld is able to be programmed by simply hand guiding the robot arm and torch through a program path to weld a part, recording those positions, and then setting the weld parameters. This easy-to-use feature enables manufacturers to train their current welding team to start, program and operate the robot in a matter of minutes as opposed to days. You do not need extensive programming knowledge to operate a cobot because programming is guided intuitively and is easy to learn and therefore extremely flexible when components change.

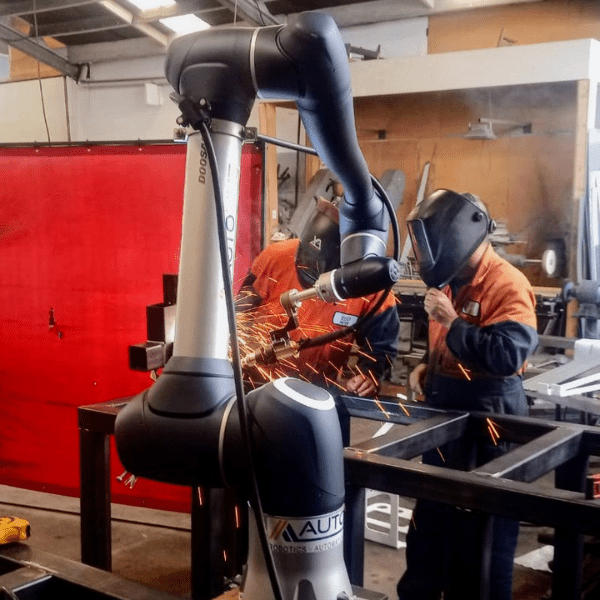

Safe to be around – Collaborative robots enable humans to safely work alongside or in close proximity to robots. When welding, manufacturers must take the proper precautions. Some of the risks associated with any kind of welding include arc flash, weld spatter and exposure to fumes and gases. The Auto-CoWeld reduces the risk to the operator to these hazards as the operator is safely removed.

Easy to relocate – A big difference between the Auto-CoWeld compared to an industrial robot welder is that the Auto-CoWeld can be used more flexible due to its lightweight design and small footprint. It is easy to relocate or reinstall the cobot elsewhere within the workshop to automate a different task should production needs change.

Increased capacity and boosted productivity – The fact that these robots are easy to teach makes them well-suited for high-mix, low-volume production runs. The use of the Auto-CoWeld for fast-paced production in low quantities also helps to reduce cycle time and maintain quality, while freeing a human work to perform other value-added tasks or complex welds that sometimes are more suited for a skilled welder rather than a robot.

Cost savings and flexibility– If a collaborative robot is running simultaneously while a skilled welder is working on another task, there is great potential to get the average dollar per part down over time, especially after a return on investment has been achieved. Experience has shown that the Auto-CoWeld system pays for itself within 12 to 18 months. The mere fact that the duty cycle (Arc ON) is approx. 25-30% for a manual welding system and approx. 60-75% for the cobot, suggests the savings.

Welds longer continuous seams – The Auto-CoWeld enables the ability to create a longer, continuous weld seam. A skilled welder can only weld about a two-foot seam in a continuous motion, while a cobot can make up to a four-foot seam. This helps to produce a higher quality weld and less downtime as their fewer starts and stops.

A challenging problem we have overcome is creating smooth welds when transitioning from circles to straight lines, click here to see the excellent quality of the welds that can be achieved with the Auto-CoWeld Welding solution.

The cobot shows all of its advantages in welding technology when:

- Components have a low to medium complexity or geometry

- Lot sizes change between small and medium

- Simple devices for the components are sufficient

Get your production up and running with the Auto-CoWeld. Installation and training are performed by Autoline robot technicians. We are there to support you every step of the way and will help you address your current welding challenges for your cobot welder application.

Robot technology for welding is a tool that makes work easier, increases efficiency and protects humans from dull, dangerous, and dirty work. The welder is relieved because he programs and operates the robot. In this way he can concentrate more intensively on high-quality, demanding welding tasks for which all his knowledge and experience are required.

Robot technology for welding is a tool that makes work easier, increases efficiency and protects humans from dull, dangerous, and dirty work. The welder is relieved because they program and operate the robot. In this way they can concentrate more intensively on high-quality, demanding welding tasks for which all their knowledge and experience are required.