Your One Stop Shop For Collaborative Applications. OnRobot delivers a full line of plug-and-produce end-of-arm tooling (EoAT) for collaborative applications. The innovative grippers, sensors, and tool changers help manufacturers gain the full advantages of collaborative and lightweight industrial robots, including ease of use, cost-effectiveness, and safety alongside human workers. The introduction of automation in the 20th century heavily shaped the industrial world and robots have been deployed in manufacturing for many years. Today, small, affordable collaborative robot arms and light industrial robots are once again revolutionizing the industrial world, giving manufacturers flexibility and increased productivity at a lower cost. OnRobot EoAT solutions help small and mid-sized manufacturers optimize their processes and grow their businesses with greater flexibility, higher output and improved quality. Collaborative automation has leveled the playing field for small and mid-sized manufacturers, and as robots become easier to buy and implement, the tooling has become the vital element in adapting for a wide range of applications. Regardless of the robot brand, OnRobot provides compatibility and versatility beyond compare. It’s everything manufacturers need from one supplier, providing even more value from the automation investment.

-

OnRobot VGP20 Gripper is the world’s most powerful electric vacuum gripper, with payloads up to 20kg (44.1 lbs) and none of the cost, complexity, and maintenance of pneumatic grippers. The VGP20 is ideal for palletizing cardboard boxes, including those made with thinner, more porous recycled cardboard, as well as bulky and irregularly shaped shipping bags. That helps shippers save even more, while also reducing waste.

OnRobot VGP20 Gripper is the world’s most powerful electric vacuum gripper, with payloads up to 20kg (44.1 lbs) and none of the cost, complexity, and maintenance of pneumatic grippers. The VGP20 is ideal for palletizing cardboard boxes, including those made with thinner, more porous recycled cardboard, as well as bulky and irregularly shaped shipping bags. That helps shippers save even more, while also reducing waste. -

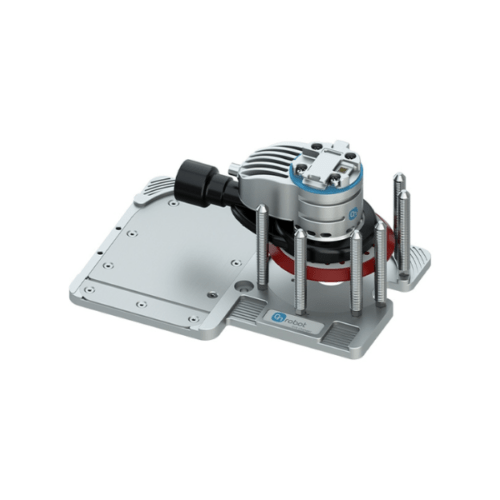

The VG10 is a compact, flexible gripping tool, which operates without an external compressor or air supply. The system is easy to install on any model of robot arm and can handle a wide variety of objects. Different sides of the gripper can be controlled independently, so can be used on multiple objects and improve the speed of operation. Since the VG10 doesn't require a compressor or air supply, it's compact and easy to move around, bringing flexibility to your production line and saving maintenance cost. It has flexible arms and adjustable vacuum enabling the VG10 to handle a variety of objects in many different sizes. It's a dual gripper - you can control the right and left sides of the vacuum gripper independently of one another, further increasing efficiency on your production line. Seamless integration with the robot of your choice. The gripper comes with dual grip functionality, tool changer and a variety of typical vacuum cups. Additionally, there are many third party vacuum cups available on the market to fit every application.

The VG10 is a compact, flexible gripping tool, which operates without an external compressor or air supply. The system is easy to install on any model of robot arm and can handle a wide variety of objects. Different sides of the gripper can be controlled independently, so can be used on multiple objects and improve the speed of operation. Since the VG10 doesn't require a compressor or air supply, it's compact and easy to move around, bringing flexibility to your production line and saving maintenance cost. It has flexible arms and adjustable vacuum enabling the VG10 to handle a variety of objects in many different sizes. It's a dual gripper - you can control the right and left sides of the vacuum gripper independently of one another, further increasing efficiency on your production line. Seamless integration with the robot of your choice. The gripper comes with dual grip functionality, tool changer and a variety of typical vacuum cups. Additionally, there are many third party vacuum cups available on the market to fit every application. -

The OnRobot Soft Gripper is able to pick a wide array of irregular shapes and delicate items, making it ideal for pick-and-place applications in food and beverage production, as well as manufacturing or packaging. The gripper is available with three interchangeable silicon-molded cups. From eggs to fruit, to bottles or cans, food and beverage automation just got easier. Like all OnRobot grippers, the Soft Gripper offers seamless integration with the robot of your choice. The Soft Gripper operates without an external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional vacuum grippers.

The OnRobot Soft Gripper is able to pick a wide array of irregular shapes and delicate items, making it ideal for pick-and-place applications in food and beverage production, as well as manufacturing or packaging. The gripper is available with three interchangeable silicon-molded cups. From eggs to fruit, to bottles or cans, food and beverage automation just got easier. Like all OnRobot grippers, the Soft Gripper offers seamless integration with the robot of your choice. The Soft Gripper operates without an external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional vacuum grippers. -

OnRobot MG10 Magnetic Gripper is a versatile, easy to use magnetic gripper for material handling, assembly and machine tending applications in manufacturing, automotive and aerospace environments. Fully compatible with all major robot brands through OnRobot’s One System Solution, the MG10 offers unique adjustable force and grip detection features that provide users with unprecedented levels of control.

OnRobot MG10 Magnetic Gripper is a versatile, easy to use magnetic gripper for material handling, assembly and machine tending applications in manufacturing, automotive and aerospace environments. Fully compatible with all major robot brands through OnRobot’s One System Solution, the MG10 offers unique adjustable force and grip detection features that provide users with unprecedented levels of control. -

The OnRobot Gecko Single Pad Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and cobots. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice.

The OnRobot Gecko Single Pad Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and cobots. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice. -

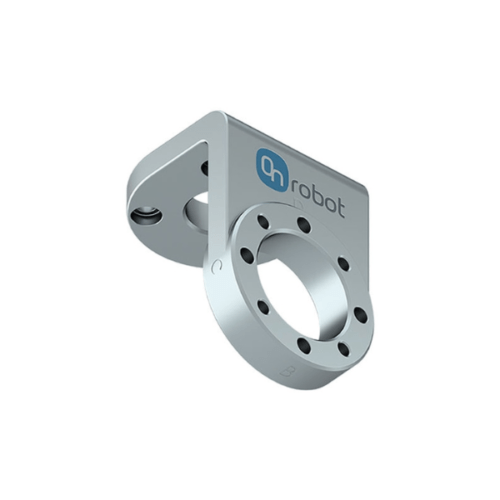

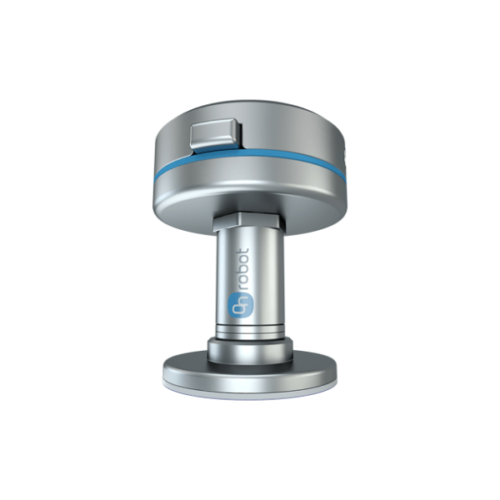

OnRobot 6-axis force torque sensors provide accurate force and torque measurements along all 6 axes. This gives you precise control when it comes to difficult assembly, polishing, sanding or deburring jobs. Additionally, the HEX software includes path recording, force control and special features for insertion tasks. This means reduced integration time for your production line. Our sensors are designed to fit most of the current industrial robot arms. Common applications are polishing, sanding, deburring, grinding and assembly, but it can also be used for teach-in and crash detection. Currently available models: HEX-E /High Precision, HEX-H /Low Deformation, HEX-E QC, HEX-H QC

OnRobot 6-axis force torque sensors provide accurate force and torque measurements along all 6 axes. This gives you precise control when it comes to difficult assembly, polishing, sanding or deburring jobs. Additionally, the HEX software includes path recording, force control and special features for insertion tasks. This means reduced integration time for your production line. Our sensors are designed to fit most of the current industrial robot arms. Common applications are polishing, sanding, deburring, grinding and assembly, but it can also be used for teach-in and crash detection. Currently available models: HEX-E /High Precision, HEX-H /Low Deformation, HEX-E QC, HEX-H QC