OTC Daihen's Robot Sensors are high precision sensing for workpiece position detection. Multiple options to accurately detect workpiece position, while also correcting curved lines and distortions. OTC Daihens precision robot sensors ensure required positioning for high-quality welding.

-

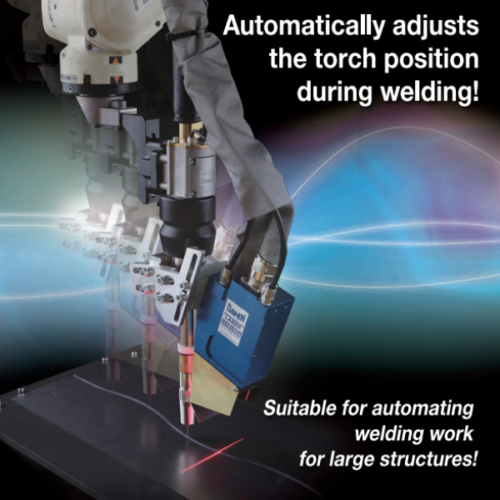

Arc Sensor FD-AR, Through-arc seam tracking with weaving. The FD-AR system is a real-time robotic seam tracking sensor used to maintain optimal welding conditions. By measuring weld data via an arc tracking system, the FD-AR determines whether production welds are living up to their quality standards.

Arc Sensor FD-AR, Through-arc seam tracking with weaving. The FD-AR system is a real-time robotic seam tracking sensor used to maintain optimal welding conditions. By measuring weld data via an arc tracking system, the FD-AR determines whether production welds are living up to their quality standards. -

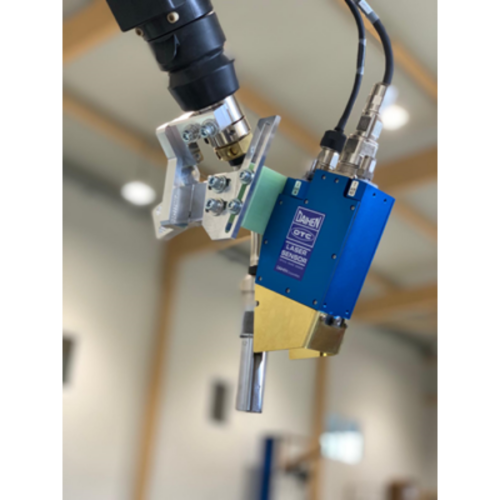

Laser Search FD-QD, High accuracy workpiece position detection with laser precision. The FD-QD (Quick Detect) is a 3D laser search system that boosts your productivity by recognizing problems before they occur. This incredible system shifts its taught programs to match the actual location of the workpieces – even with difficult joints. FD-QD is well suited for a variety of applications, including standard MIG, TIG, and air plasma cutting.

Laser Search FD-QD, High accuracy workpiece position detection with laser precision. The FD-QD (Quick Detect) is a 3D laser search system that boosts your productivity by recognizing problems before they occur. This incredible system shifts its taught programs to match the actual location of the workpieces – even with difficult joints. FD-QD is well suited for a variety of applications, including standard MIG, TIG, and air plasma cutting. -

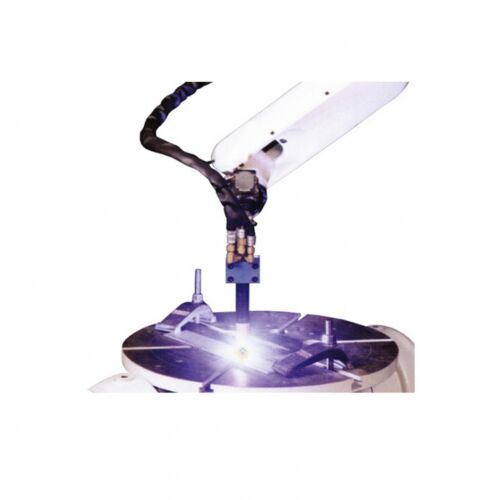

Touch Sensor FD-WD, Touch sensor for workpiece position and detection. The FD-WD and FD-WD-H sensors enable a robotic deviation detection system used for finding linear changes in a part. Wire sensing is the most common sensing method available. No additional hardware is required (all sensing is performed via the weld wire).

Touch Sensor FD-WD, Touch sensor for workpiece position and detection. The FD-WD and FD-WD-H sensors enable a robotic deviation detection system used for finding linear changes in a part. Wire sensing is the most common sensing method available. No additional hardware is required (all sensing is performed via the weld wire). -

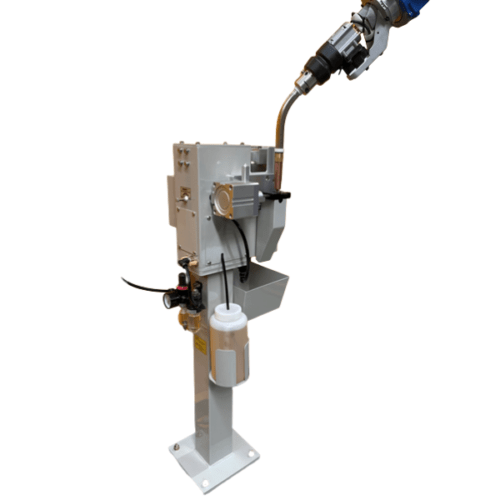

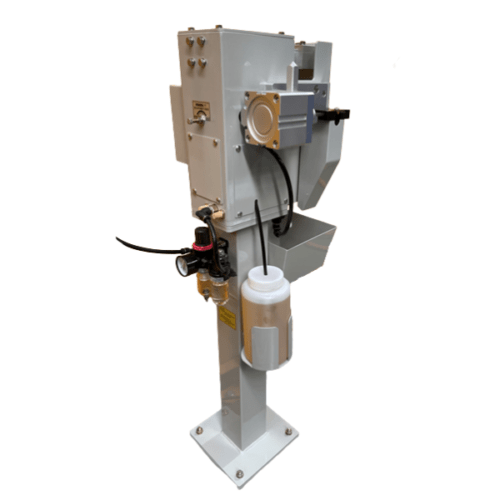

A clean weld is important to ensuring the highest possible quality of operation. The OTC Daihen Clean Kit can automatically and effectively clean the welding torch nozzle, apply splatter inhibitors, and carry out brushing or wire cutting functions as needed. This allows the welding robot to operate at the most efficient possible rate.

A clean weld is important to ensuring the highest possible quality of operation. The OTC Daihen Clean Kit can automatically and effectively clean the welding torch nozzle, apply splatter inhibitors, and carry out brushing or wire cutting functions as needed. This allows the welding robot to operate at the most efficient possible rate. -

Welbee Co-R is a welding application that enables the connection between the widespread collaborative robot and the Weibee series, the highest model of Daihen. The torch mount and robot software specialized for welding work by collaborative robots support the introduction of robots at welding sites. Welbee Co-R, which is packed with Daihen's know-how, proposes a new form of welding automation. Certified as a peripheral device platform for Universal Robots (UR). Cobot brands also include: Doosan Robotics, TM, Omron

Welbee Co-R is a welding application that enables the connection between the widespread collaborative robot and the Weibee series, the highest model of Daihen. The torch mount and robot software specialized for welding work by collaborative robots support the introduction of robots at welding sites. Welbee Co-R, which is packed with Daihen's know-how, proposes a new form of welding automation. Certified as a peripheral device platform for Universal Robots (UR). Cobot brands also include: Doosan Robotics, TM, Omron